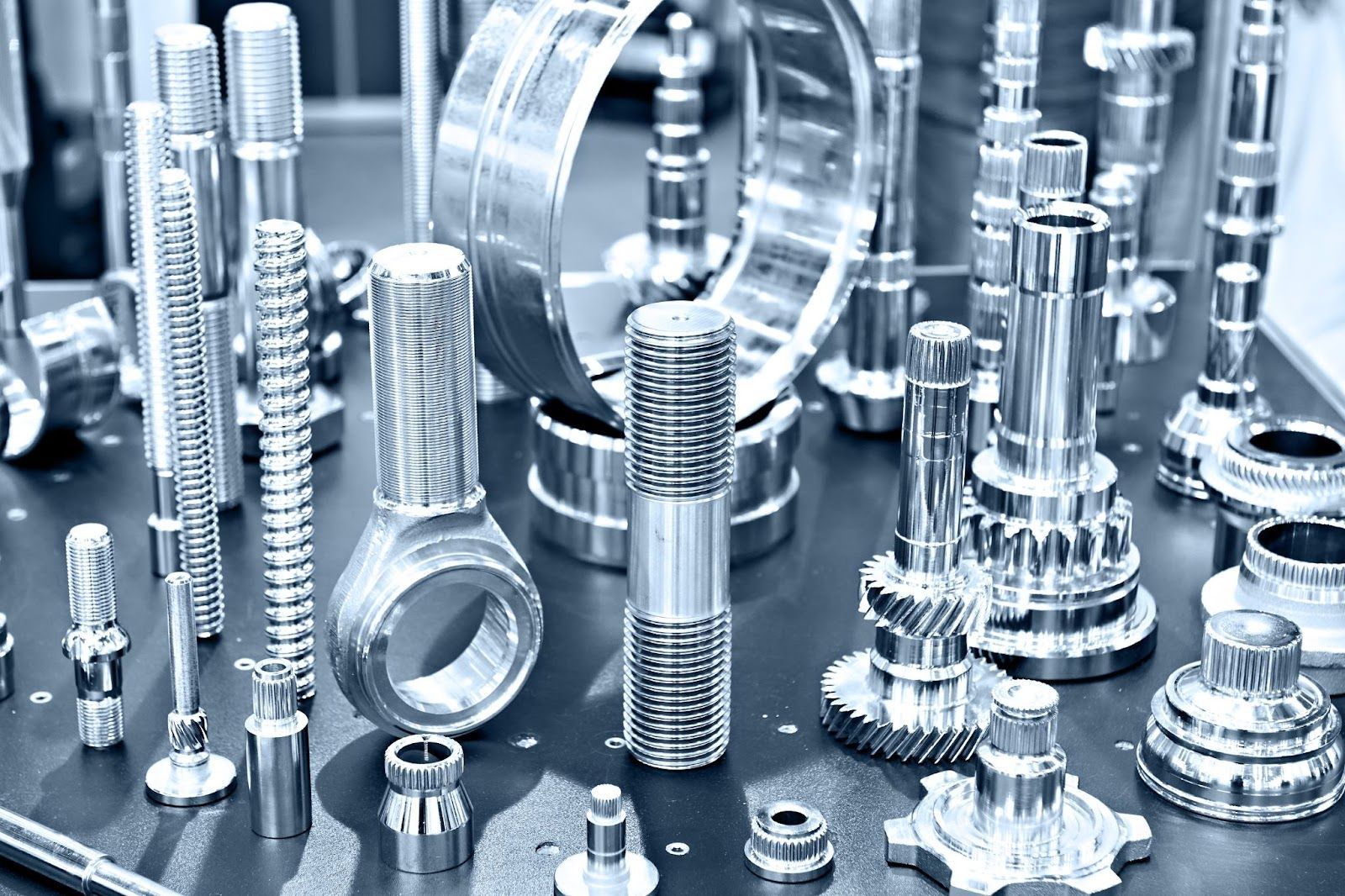

6 Types Of Common Machine Components

With time, mechanical engineering has grown incredibly complex. If we count each component down to the tiniest screw, the average car nowadays contains roughly 30,000 machine parts. These component parts function together to operate the car as envisioned by the machine's design.

While some of these mechanical components are merely basic building blocks, others are assembled with other components and serve a specific purpose for the car. Such components include but are not limited to the carburettor, engine, and alternator.

Understanding machine components is the first step in building effective machines that address urgent issues. They considerably outperform human capabilities while reducing human effort.

So, let's take a closer look and better understand these common machine components.

What Are Machine Components?

The smallest mechanical part or component assembly in a machine is a machine component in mechanical engineering. They typically carry out a single task and cannot be replaced by additional elements. As a result, a machine component can be described as a discrete element or section of a machine.

The Different Types Of Machine Elements

Basic mechanical parts that work together to make a machine work include general and unique purpose machine elements. Here are some examples of common machine components and their functions.

Bearings

In the design of machines, bearings are among the most popular machine components. The purpose of their function is to reduce friction between two moving elements. Without it, rotating machines' mechanical designs are incomplete.

The main goal of bearings is to avoid direct metal-to-metal contact between the two components and to allow for smooth relative motion. They are available in a variety of sizes and shapes.

Given the variety of bearing design options available, designers can choose the optimal bearing for a given application while still achieving the highest levels of the following requirements:

- Dependability

- Efficiency

- Performance

- Durability

Applications for bearings include the following:

- Sliding doors/windows/drawers

- Engine crankshaft

- Conveyor pulleys and idlers

- Wind turbines

- Motors

Shafts

Shafts are long, cylindrical parts that transmit mechanical power and torque between two components. When the distance between drive train parts is too vast for a direct connection or if they function in various conditions, designers incorporate them.

Depending on the situation, a shaft could be solid or hollow. While hollow ones have a better load-carrying capability for the same weight, solid ones are more compact. Hollow shafts are preferred by designers for shafts that must withstand severe operating loads because they have higher rigidity, stiffness, and bending moments.

The following are some applications for shafts:

- Clocks and watches

- Vehicle axles

- Pumps

- IC engine crankshafts/camshafts

- Motor

Keys

Keys are small mechanical parts used in machine design to join shafts to spinning parts. They might occasionally be responsible for transferring torque between the two parts.

In order to secure the key in place, cutouts are made in both the shaft and the rotating element for keys inserted between them. Keyway refers to the hole in the hub. The keyseat is the area at the bottom of the keyway where the key rests inside the shaft. An entire assembly is referred to as a keyed joint.

Since keys are inserted in the axial direction, a keyed joint may only enable a small amount of axial mobility but does not permit relative rotational motion. As a result of their purpose, keys must withstand significant compressive and shearing pressures. Therefore, when designing a key's mechanical structure, it's crucial to consider crushing and shearing failure.

In machine design, several common shapes exist for the many types of keys. The five major types of keys include:

- Round

- Saddle

- Spline

- Sunk

- Tangent

Applications for keys include:

- Pulleys

- Sprockets

- Marine propeller

- Gear drives

- Motor

Couplings

In mechanical design, couplings are mechanical parts that join two rotating in-line shafts and serve primarily to transmit power. The assembly rotates at the same speed as a whole. Depending on the situation, a connection may be rigid or flexible.

Flexible coupling can absorb any installation mistakes and minor shaft misalignments that may occur over time. Additionally, they deflect vibration and stress, extending the equipment's functional life in the process.

Couplings do not engage and disengage as clutches do. In some applications, these machine components also isolate the heat transmission between the two ends.

Some couplings function like fuses. They terminate the connection between the driving and driven components to safeguard sensitive machinery if the torque exceeds a predetermined threshold.

Examples of couplings applications include:

- Paddle steamers

- Motion control in robotics

- Generators

- Automotive steering linkages

- Car differentials

Fasteners

Several kinds of fasteners are used in mechanical engineering applications to join two or more equipment components. When necessary, they can be disassembled to produce temporary joints. Specific equipment operates in harsh environments. As such, fasteners are primarily used to safeguard these types of equipment from the following:

- High pressures

- Excessive stresses

- Vibration

This is to guarantee that these machine components can control the forces that the product will encounter during application and that the machines will operate well. The most common types of steel used to make fasteners are as the following:

- Alloy

- Carbon

- Stainless steel

Gears

Basic machine components known as gears transmit rotation and power between two shafts. Following the laws of energy conservation, they are able to change the angular velocity while also altering the torque. They function as levers in a machine translation system.

In order to transfer energy from the driving shaft to the driven shaft, two gears' teeth must engage with one another. Although the shafts are typically parallel, several gears can transfer power between intersecting and non-intersecting shafts.

Here are a few applications for gears:

- Vehicle gearboxes

- Mixers and blenders

- Clocks and watches

- Washing machines and dryers

- Clocks and watches

Understanding The Purpose Of These Machine Components Is Vital To Design Any Effective Machinery

While the common machine components are small, they play an important role in ensuring that any heavy machinery can function efficiently and effectively. There are also characteristics for these machine components to help you differentiate between a component for general-purpose or special-purpose machinery.

Looking for high-quality heavy equipment spare parts in Malaysia? Choose Choong Ngai Engineering!

So, if you're looking for a sheet metal contractor in Malaysia, visit us at Choong Ngai Engineering today to speak to our experts. We at Choong Ngai Engineering have years of experience and knowledge to answer your doubts or concerns, and we ensure to provide you with the quality solution you're looking for. Call us now!