10 Interesting Facts That You May Not Know About Welding

With tools that date as far as 1000 B.C., welding has been a practice for generations. When blacksmithing developed in the mediaeval times, most metal objects produced were welded using hammering techniques.

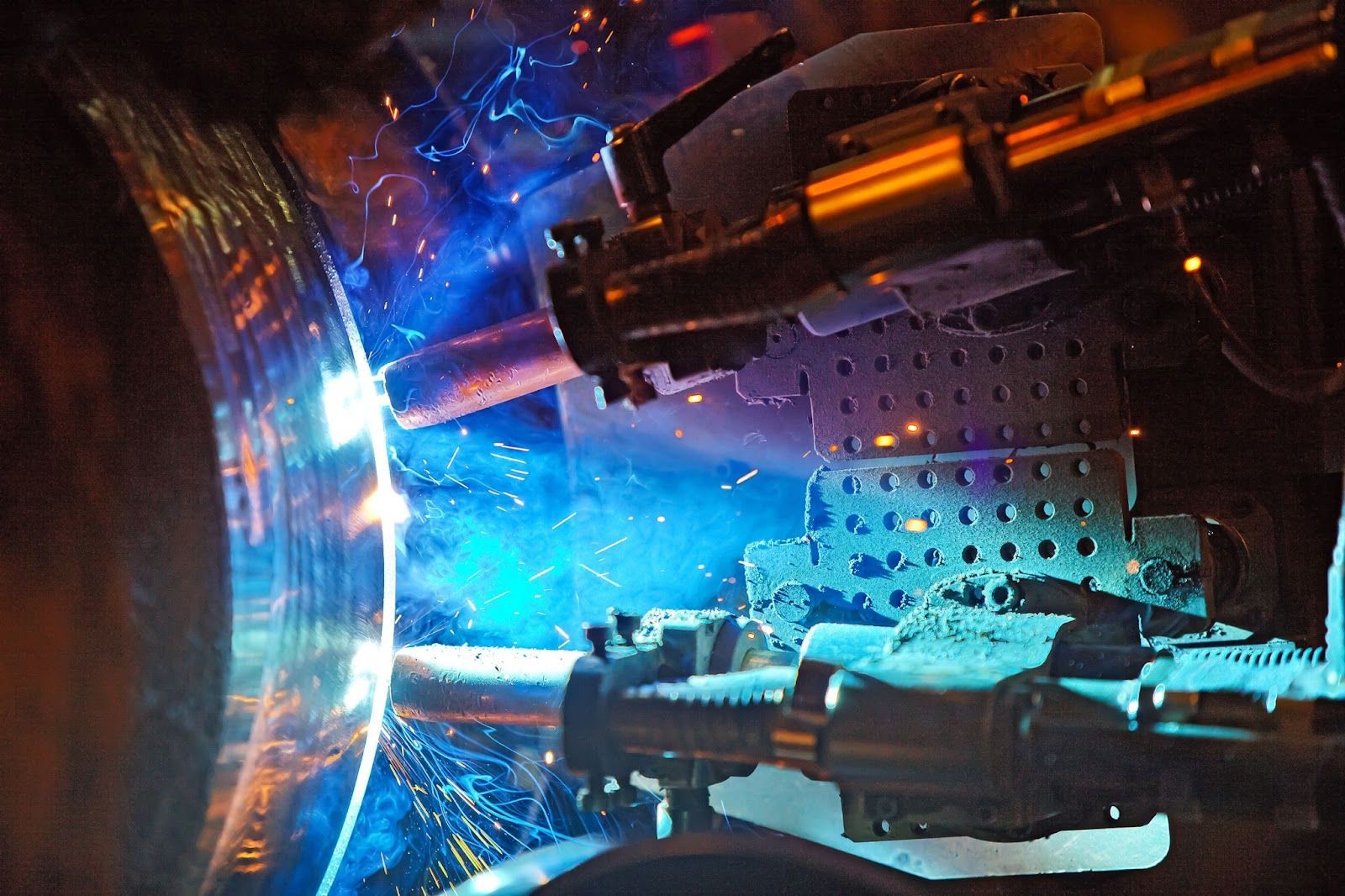

Welding is joining metal pieces together by melting the metal using intense heat. The metal solidifies and creates a strong bond as it cools. Most industries use welding, but steel construction uses it more than any other since it allows for the reliable creation of strong structures from various materials.

With such a long history that dates back to centuries, there are bound to be fascinating facts you may need to learn about welding. So, here are ten exciting facts to enlighten you about welding.

Welding Dates Back To Thousands Of Years

One of the earliest innovations we know of is welding, which we estimate has existed for at least 10,000 years.

Through smelting, civilisations used copper and tin to create tools and weapons during the Bronze Age. They heated the rocks until they were molten, added some metal ore, and heated it again until it melted along with the rock.

Additionally, there is proof that humans who lived close to modern-day Turkey during the Iron Age were skilled at producing iron and steel by heating rocks and adding charcoal. They would then use that molten liquid to build anything they want by pouring it into a mould.

The Fastest Ship Ever Built Was Welded

The SS Robert E. Peary continues to hold the title of the fastest ship ever constructed. It took only four days, 15 hours, and 27 minutes to create a WWII liberty ship. Due to the rapidly evolving welding processes and innovations, ships like these could be constructed more quickly and effectively.

The Highest Temperature Can Be Found In Welding

Gas welding (oxyacetylene welding) has the highest temperature of all welding processes. This technique produces extremely high temperatures of around 3,500 degrees Celsius using a blend of fuel gases and oxygen. Welding generates heat at roughly 3400 K, while the sun creates heat at 5800 K.

WWI And WWII Played A Pivotal Role In Welding

Many military forces studied welding during World War I to identify which techniques would produce the most remarkable outcomes for military technology and equipment, leading to the development of the following:

- First welded ships and warplanes

- Improvements in bridge construction and other areas

With the introduction of shielding gas in the 1920s, welding technology continued to develop. Similar to World War I, World War II saw significant advancements in welding technology, including:

- Alternating current

- Welding fluxes

- Mechanised welding

In 1941, Gas Tungsten Arc Welding (GTAW) was made flawless.

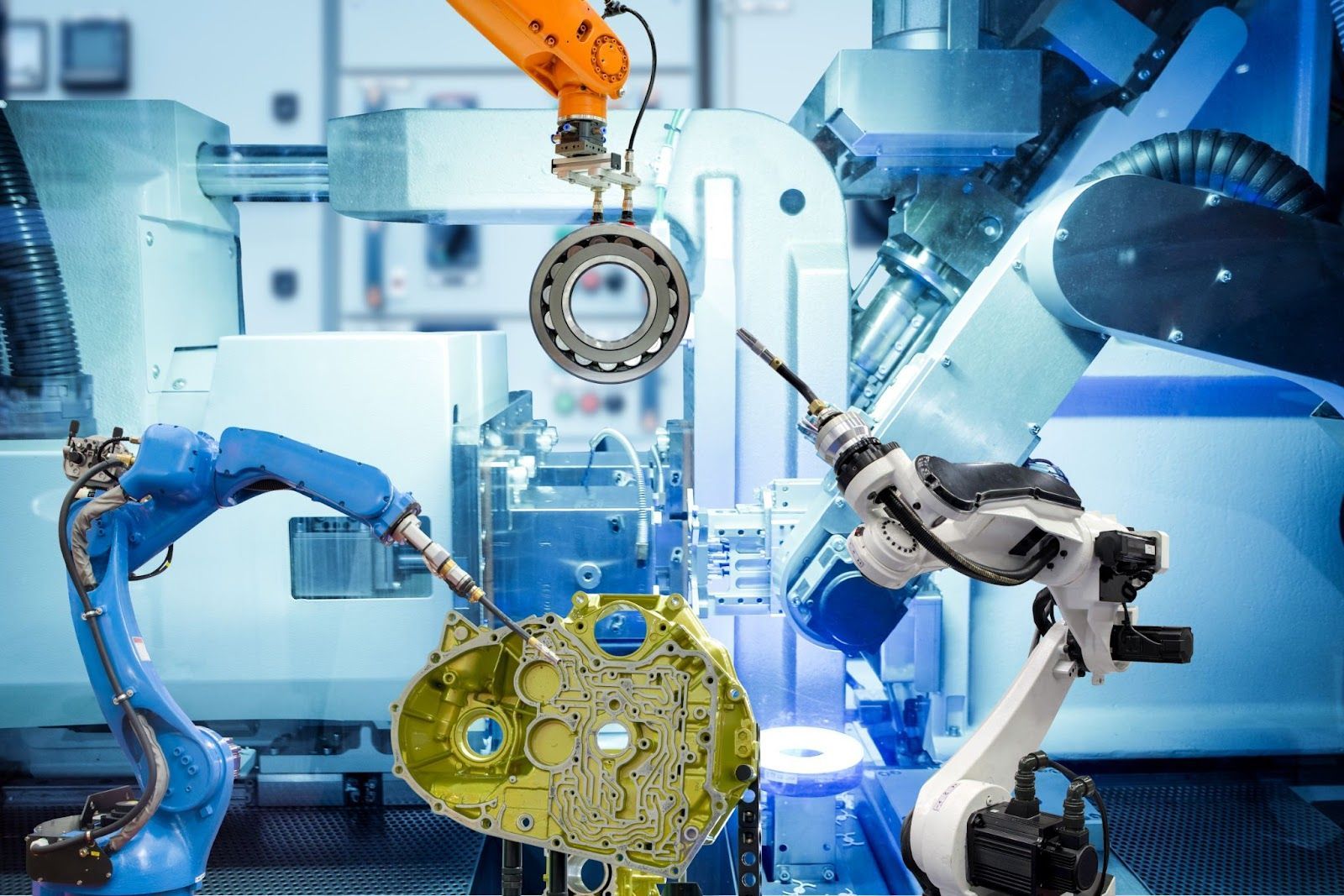

Various Industries Utilises Welding

Almost every sector can benefit from welding in some way. The most prevalent uses include:

- Architectural and structural metals manufacture

- Motor vehicle manufacturing

- Mining

- Agricultural manufacturing

Other significant employment in the welding profession include:

- Shipbuilding industry

- Aerospace industry

Over 50% of all products manufactured by humans reportedly need welding. Additionally, welding is required before various modes of transportation, buildings, and structures can be used.

The First Workable Industrial Robot Was Designed To Weld

The first industrial robot developed was intended for welding. In 1961, George Devol created the design. He named it the Unimate, and it could be programmed to precisely repeat specific actions to execute welding activities on vehicles such as:

- Cars

- Trucks

- Missiles

Welding Made It To Space

During the Apollo-Soyuz Test Project in 1969, the first welding technique was performed in space. While on the Soyuz spacecraft, Alexei A. Leonov utilised special tools to construct a helical antenna. It was made entirely of metal, which was necessary for evaluating the interoperability of American and Russian technologies.

Explosion Welding Is Also A Type Of Welding Process

Fundamentally, it functions as the name implies: metals are fused via controlled explosions, preserving their natural qualities. It is employed explicitly for combining incompatible metals and non-metals.

Welding Relied Heavily On The Invention Of Electricity

Welding was not used to advancing industries until around 1831 and 1879, when electricity was created. Before welding could be utilised, electricity had to be used to build other equipment, such as generators and motors.

In theory, welding could not accomplish much without the development of electricity. However, without the fundamental welding techniques that were already in place, electricity most likely would not have been developed.

Resistance welding is a type of welding that was created in 1885 by William W. Jacques and used electricity as its primary heat source.

Both Wet And Dry Welding Exist

Wet welding is differentiated from dry welding by the fact that the former is carried out in an area that is surrounded by water. The latter is shielded from it, at least in significant volumes. Even underwater welding doesn't necessarily require direct contact with water; most welding is still done in dry conditions.

Looking for metal welding services in Malaysia? Visit Choong Ngai Engineering now!

Prior to selecting a welding technique, it is crucial to consider the complexity and quantity of the parts that will be welded. Time and cost plays an important role as well so be sure to keep that in mind.

If you're looking for a reliable quality welding services provider in Malaysia, look no further than Choong Ngai Engineering Works. We are a leading provider of quality welding services Malaysia and provide the best possible service to our clients. Contact us now!