The Types Of Machines That Are Used In The Metal Industry

The metalworking industries utilise a broad range of various types of industrial tools to produce metal products with the desired shape and size. For several centuries, these machines have developed to the point that they can now make even the most intricate shapes with far less manual labour.

The fabrication business uses various techniques that have sparked the creation and development of multiple pieces of equipment. With such a wide range of machines, it's critical to comprehend the many types and what each one is capable of.

So, let's take a look at the different types of machines that are being employed in the metal industry.

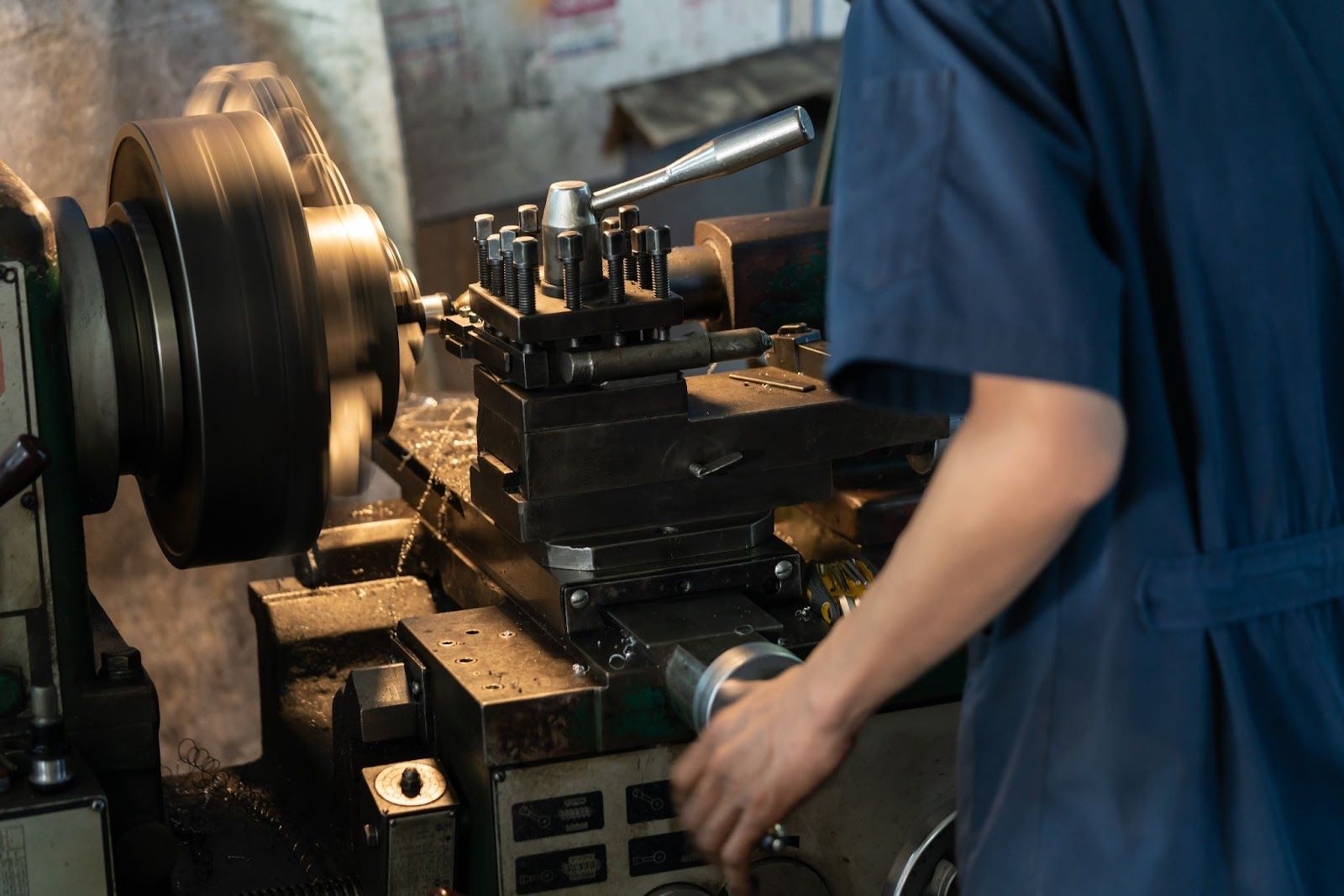

Lathe Machine

For various machining tasks, lathes are metalworking devices that spin the material. Lathes can be used to make parts from ferrous and nonferrous metals, polymers, and wood.

They can be used for a variety of tasks, including:

- Cutting

- Sanding

- Knurling

- Drilling

- Boring

- Threading

- Facing

- Turning

Additionally, they have a wide selection of attachments and come in different sizes. The majority of labour done on lathes is precise work, and they have been around since prehistoric days.

In addition to metalworking and machine shops with heavy-duty machines, they can be found in businesses that manufacture parts for light machinery.

Milling Machine

A piece of equipment for metalworking known as a milling machine removes unwanted material using rotating cutters. The portable work table, which allows a spinning tool to be moved vertically around it, securely holds the workpiece in place.

A milling machine conducts two important processes:

- Face milling

- Peripheral milling

In contrast to peripheral milling, where the cutter is positioned parallel to the workpiece, face milling involves the operator milling a flat surface at a right angle to the cutter's motion.

Their uses range from straightforward cutting to intricate shaping and drilling. Due to their adaptability, milling machines are a standard in most metalworking facilities.

Grinding Machine

An abrasive wheel is designed to rotate at a comparatively high speed using a grinding machine. The rotating wheel finishes the project by removing a very small portion of material over its surface, leaving it smooth to the touch.

Grinders have a variety of functions on workpieces that have been cut with other instruments, such as saws or lathes. Those functions include:

- Shaping

- Flattening

- Smoothing

To prepare parts for repainting or refurbishment, abrasive compounds can also remove paint or corrosion. Grinding machines are a crucial component of every metal manufacturing process due to their versatility and precision.

Drilling Machines

In metalworking industries, drilling machines are among the most common types of equipment people encounter. They are frequently used for a variety of home repairs as well.

Drilling machines are straightforward to operate because the tools are easy to install and replace. They can be utilised to drill holes into a wide range of materials, such as:

- Metals

- Cement

- Concrete

Shaper Machines

The cutting process on a workpiece is carried out by a shaper machine using a single-point cutting tool that operates in a linear motion. It is easy to use and has a straightforward mechanism.

To get the desired shape on a workpiece, these mill machines can perform the following functions:

- Cut

- Shape

- Form

Shaper machines are often installed on a table to reach the material from all angles. Sheet metal is one material that benefits from these machines since they make complex shapes like an arc with just one pass. As you may expect, they are widely used in the industry.

Broaching Machines

A broaching machine can be used to perform various functions on a range of materials. Those functions include:

- Cutting

- Shaping

- Forming

Additionally, it removes material from the workpiece with a toothed tool or a broach. The two different broaching methods are:

- Linear

- Rotational

The more popular of the two is linear broaching, which involves aligning the machine with the workpiece. However, with rotary broaching, the broach rotates while it is applied to the workpiece.

In many various sectors, broaches are a useful tool with many applications. For industry experts who work on metalworking projects, they produce a wide variety of diverse products.

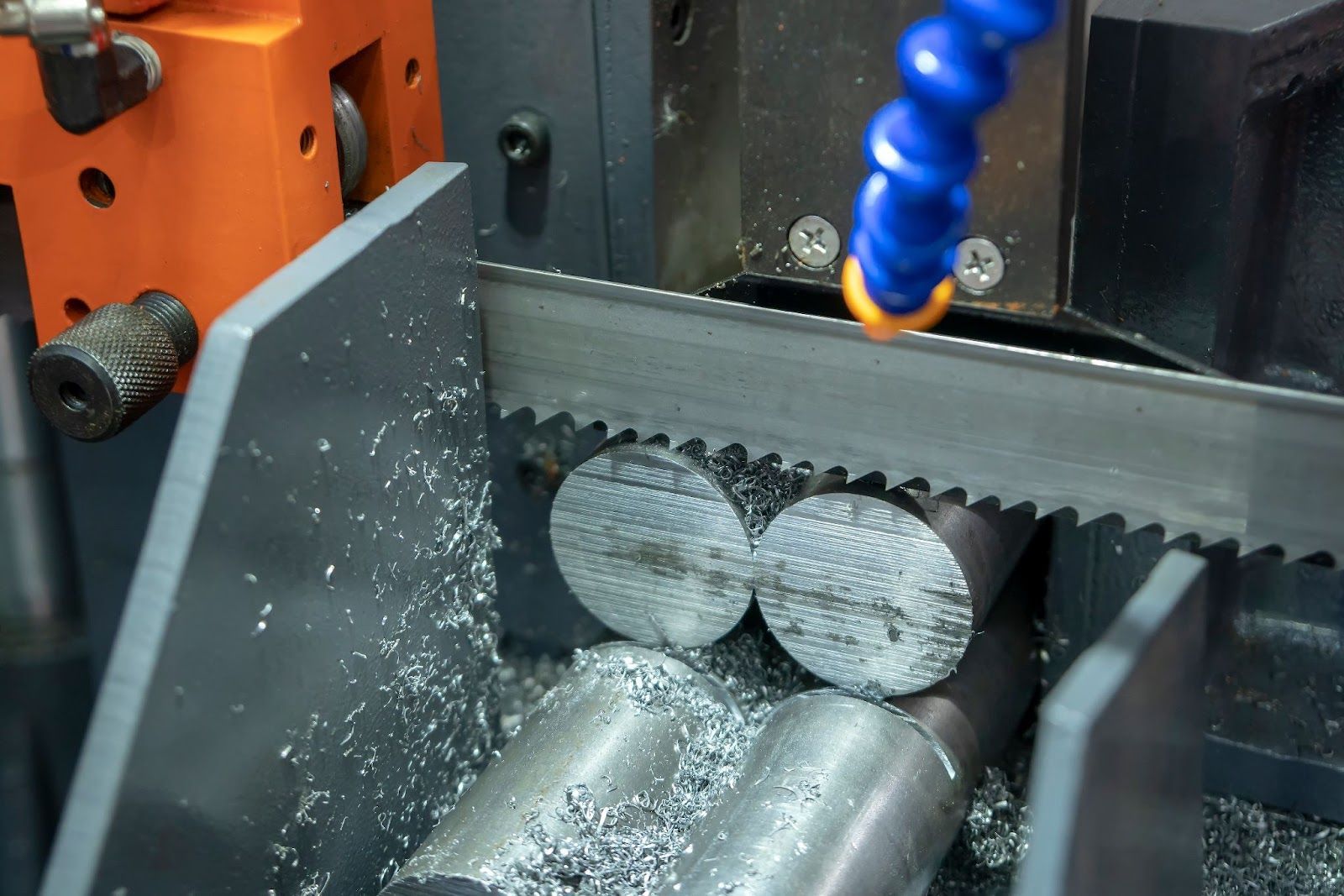

Saw Machines

The hacksaw, circular, and band saw are the three different forms of sawing equipment. A metal object is divided into smaller pieces using this equipment.

Band Saw

For cutting wood and metal, the band saw is a fantastic tool. Large quantities of long components in any required length can be produced using it, including solid bars or pipes.

Circular Saw

Both handheld and tabletop circular saws utilise a circular blade that reciprocates or rotates to cut. One of the most useful saw equipment for industrial applications is the circular saw.

Hacksaw

Hacksaws are arguably the most popular saws. This hand-operated tool has a straight blade with several tiny teeth for cutting through all kinds of metal materials, including:

- Pipes

- Rods

- Sheet metal

Planer Machine

Shaper machines and planar machines have a lot in common. The main difference with this machine is that the cutting blade is fixed, and the workpiece moves in a linear motion. These devices are often bigger than shaping equipment.

By removing some additional material during machining operations, they are used to reduce the thickness and size of materials like:

- Steel plates

- Bars

- Rods

Additionally, it is utilised to create flat surfaces from textured or uneven surfaces.

Shearing Machine

Sheet metal is trimmed into the required shapes and sizes using a shearing machine. The shearing process does not produce chips or any other leftover material, reducing dust in the atmosphere and the floor. As such, these metalworking machines are perfect for industrial facilities.

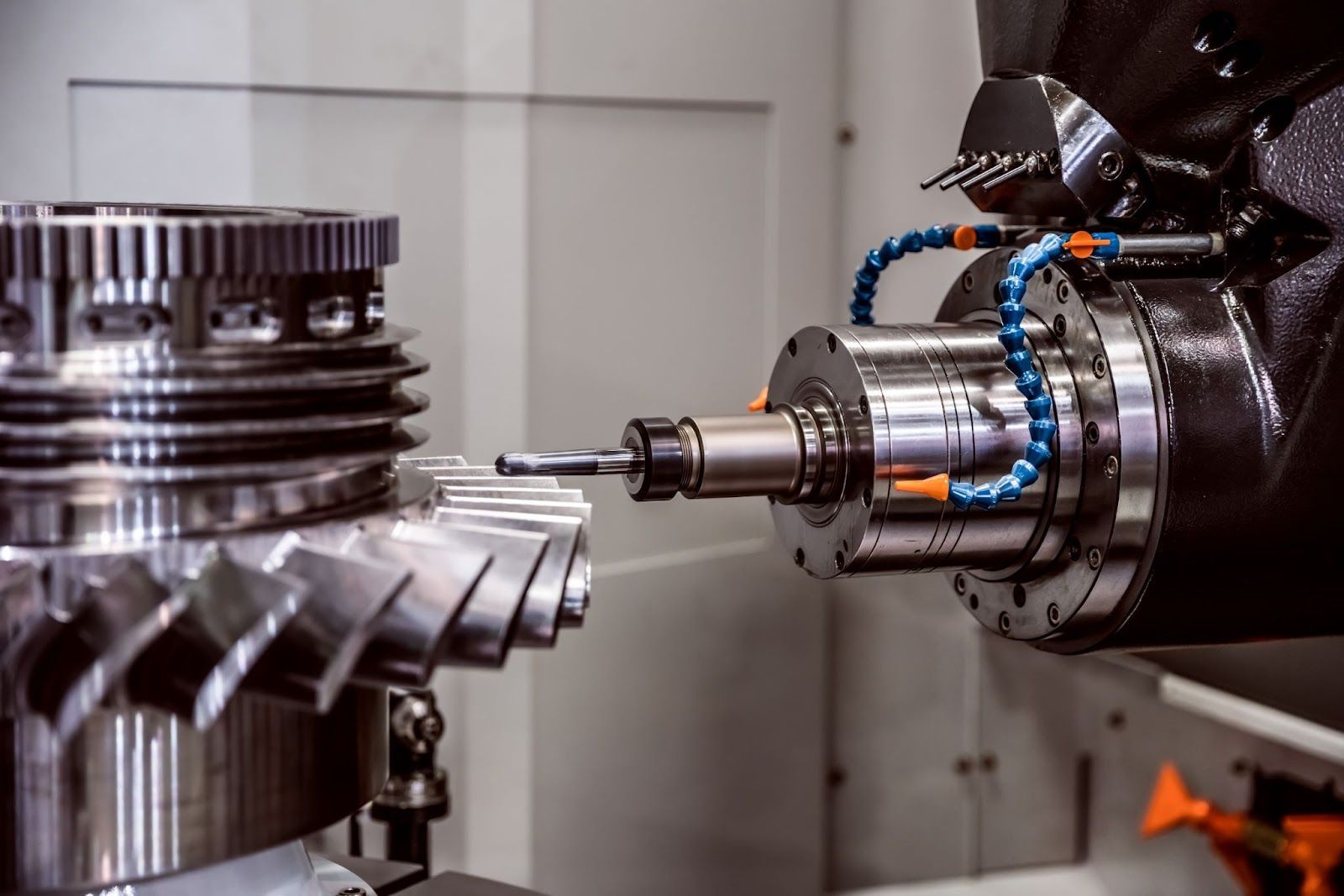

Hobbing Machines

The effectiveness and quality of manufacturing processes have been greatly enhanced by using hobbing machines in the metalworking field. They are a type of milling machine that creates the following:

- High-precision shafts

- Gears

- Splines

- Other cylindrical parts (required for several applications using a particular kind of cutting tool)

To suit their needs, a standard metalworking facility will be equipped with at least one or two hobber machines available. They can produce a large number of parts every day while only needing a few staff to operate. In addition, a hobbing machine is also relatively inexpensive.

Drill Press

To accomplish drilling operations, a drill press is a piece of equipment that is frequently used in the metalworking industry. It can be operated manually or electrically, and it often has a work surface known as the bed that enables the drill bit to be positioned vertically.

They are more stable than comparable handheld drills and are a more reliable alternative. The workstation enables continuous and incredibly accurate drilling.

For hundreds of years, drill presses have been used in the metalworking industry. Since then, a lot has evolved, and new inventions have made it simpler than ever to finish metalworking tasks swiftly and effectively.

Looking for a high quality plate rolling service in Malaysia? Try Choong Ngai Engineering

While there are many types of machines used in the metal industry, the ones we’ve shared are the common ones you can expect, especially for metal fabrication. By knowing the different types of machines out there, you may be able to find the right company to help you in your metal customisation quest.

So if you're looking for metal bending services in Malaysia, visit us at Choong Ngai Engineering today to speak to our experts. We at Choong Ngai Engineering have years of experience and knowledge to answer your doubts or concerns, and we ensure to provide you with the quality solution you're looking for. Call us now!