5 Types Of Metals And The Proper Way To Use Them

Since the Bronze Age, humankind has looked for new ways to create, refine, and use metal. The possibilities and utilisation of the thousands of different types and metal grades are only limited by our imagination.

Metals have aided in the advancement and expansion of our society and civilisation as a whole since they serve as the core of numerous businesses and the original cause of the Industrial Revolution.

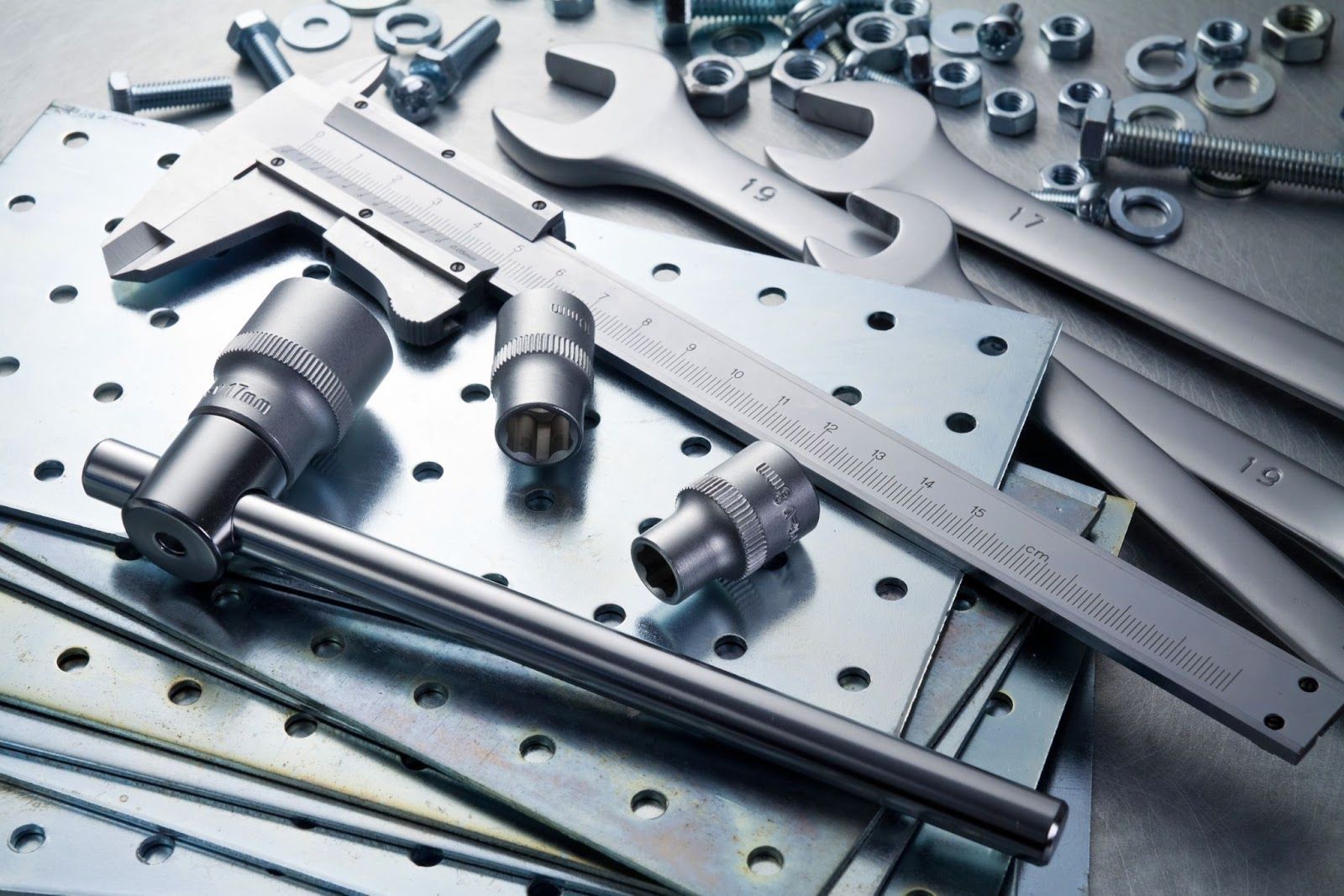

We are constantly surrounded by at least 80 forms of metal, from household equipment to residential buildings and infrastructure. The five metals listed below are among the most widely used worldwide for custom metal fabrication.

Steel

Steel is an iron alloy that has been enhanced with about 1% carbon and is often free of the impurities and leftovers typically present in iron. Iron is hefty, thick, and prone to corrosion despite being a stronger metal than other metals. These factors make building and maintaining structures made entirely of iron challenging.

Adding carbon to iron mitigates these vulnerabilities and strengthens the material. Compared to other forms of metal, steel also has a relatively high strength-to-weight ratio, making it possible to produce small but powerful steel parts.

Steel is the most utilised metal in the world, with over 3500 different grades and about 2 billion tonnes produced worldwide yearly. There are many distinct forms of steel since so many other components with various properties are combined to make steel alloys, which is ideal for custom metal fabrication.

Alloy Steel

When iron and other substances are combined, alloy steel is the product. The components that are sometimes used to combine in alloy steel include:

- Chromium

- Manganese

- Nickel

- Tungsten

- Vanadium

Alloy steel is particularly adaptable since each alloying element contributes a unique set of qualities to the combination.

The exact alloy can be altered to provide a variety of desired properties, some of which might include increased material strength or a product that is more resistant to wear and corrosion, based on the project's needs. Due to its low production costs, alloy steel is used extensively in custom metal parts.

Stainless Steel

Stainless steel is an alloy steel made of the following materials:

- Iron

- Carbon

- Considerable amounts of chromium

- Byproducts of other metals that are highly corrosion-resistant

It is a flexible material that is frequently used in households and other stainless steel custom made items in Malaysia. Stainless steel is ideal for the production of anything that comes into touch with food because it doesn't rust quickly, including:

- Kitchen utensils

- Tables

- Sinks

Carbon Steel

Iron and carbon are combined to create carbon steel, which occasionally contains trace amounts of other metals. Based on how much carbon is included in the alloy, it is frequently divided into three groups:

- Low carbon steel

- Medium carbon steel

- High carbon steel

The more carbon is utilised in the production of steel, the tougher the alloy. However, a carbon-free alloy is easier and less expensive to produce when it contains only a small amount of carbon. Although it is frequently used to make tools and custom metal parts, carbon steel is best recognised as a structural building material.

Tool Steel

Tool steel's toughness makes it ideal for cutting, drilling, and other shock-resistant tools. Iron can be made harder by alloying it with substances like:

- Cobalt

- Molybdenum

- Tungsten

- Vanadium

There are several uses for tool steel, including:

- Construction

- Shipbuilding

- Automobile industries

It is typically employed to machine and alter various types of steel.

Iron

Iron is a prevalent and well-liked metal that makes up about 5% of the Earth's crust and is the sixth most common element in the universe. Unalloyed iron is an unstable substance that readily produces iron oxide when it combines with atmospheric oxygen.

Steel is frequently created by alloying it with other elements to increase its stability for custom metal fabrication. Due to its porous surface and the anti-stick properties of heated oil, iron is used in cookware.

Cast iron is utilised in creating wood stoves because of its very high melting point. Iron is a heavy metal; as a result, it provides stability and reduces vibrations, resulting in it being frequently used to make the frames and bases of large machines.

Aluminium

Bauxite, the metal's resource, is what gives aluminium its characteristics, including:

- Durability

- Lightweight

- Corrosion resistance

Aluminium was created in the 19th century and has since gained popularity due to the following factors:

- Machinability

- Electrical conductivity

- Lack of magnetism

Additionally, aluminium is the most common non-ferrous metal on Earth and is renowned for its malleability and capacity to combine with nearly every other metal to produce alloys. While it does not rust, aluminium has a great strength-to-weight ratio. However, when exposed to salt, aluminium oxidises and corrodes.

Applications for it range widely, including:

- Cans

- Home appliances

- Aeroplanes

Zinc

With a low melting point, zinc is a common metal. It is easy to recycle since zinc flows effortlessly when it is melted. Although it has a low electrochemical potential, the finished product is highly durable making it ideal for custom metal fabrication. Zinc is utilised to coat and protect other metals, in addition to preventing galvanised steel from rusting. Its uses include:

- The industrial

- Marine

- Medical sectors

- Hardware industry

- Electrical industry

- Automotive industry

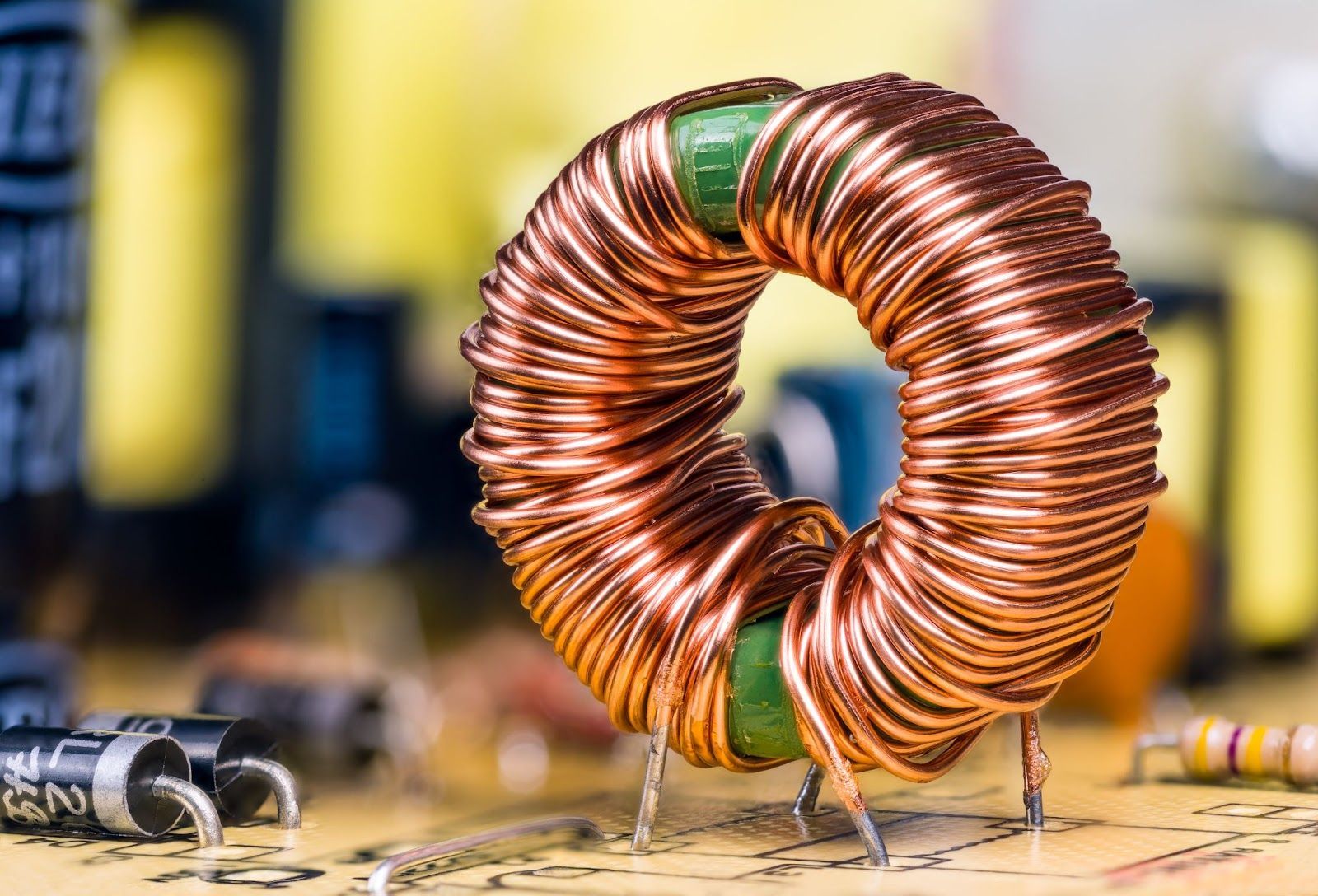

Bronze

Bronze is created by alloying copper and tin with occasionally trace amounts of other elements like:

- Silicon

- Aluminium

- Manganese

- Phosphorus

The "Bronze Age" refers to the period of time when bronze was the first alloy created by humankind. Despite its brittleness, bronze is a durable element that endures fatigue and does not bend or split.

Owing to its strong thermal and electrical conductivity and excellent corrosion resistance, it is widely used to produce the following objects:

- Electrical connectors

- Church bells

- Ship components

- Reflectors

Looking for the best custom metal fabricator in Malaysia? Choose Choong Ngai Engineering!

Metals come in a variety of forms, and while there are as many uses for metal as there are types, these popular metals are frequently utilised because of their strength and adaptability. The foundation of our existence is fabrication, and we couldn't live with half the things we do now without these metals.

So, if you're looking for a custom metal fabricator in Malaysia, visit us at Choong Ngai Engineering today to speak to our experts. We at Choong Ngai Engineering have years of experience and knowledge to answer your doubts or concerns, and we ensure to provide you with the quality solution you're looking for. Call us now!