Expert Welding Services in Malaysia for Stainless Steel Work

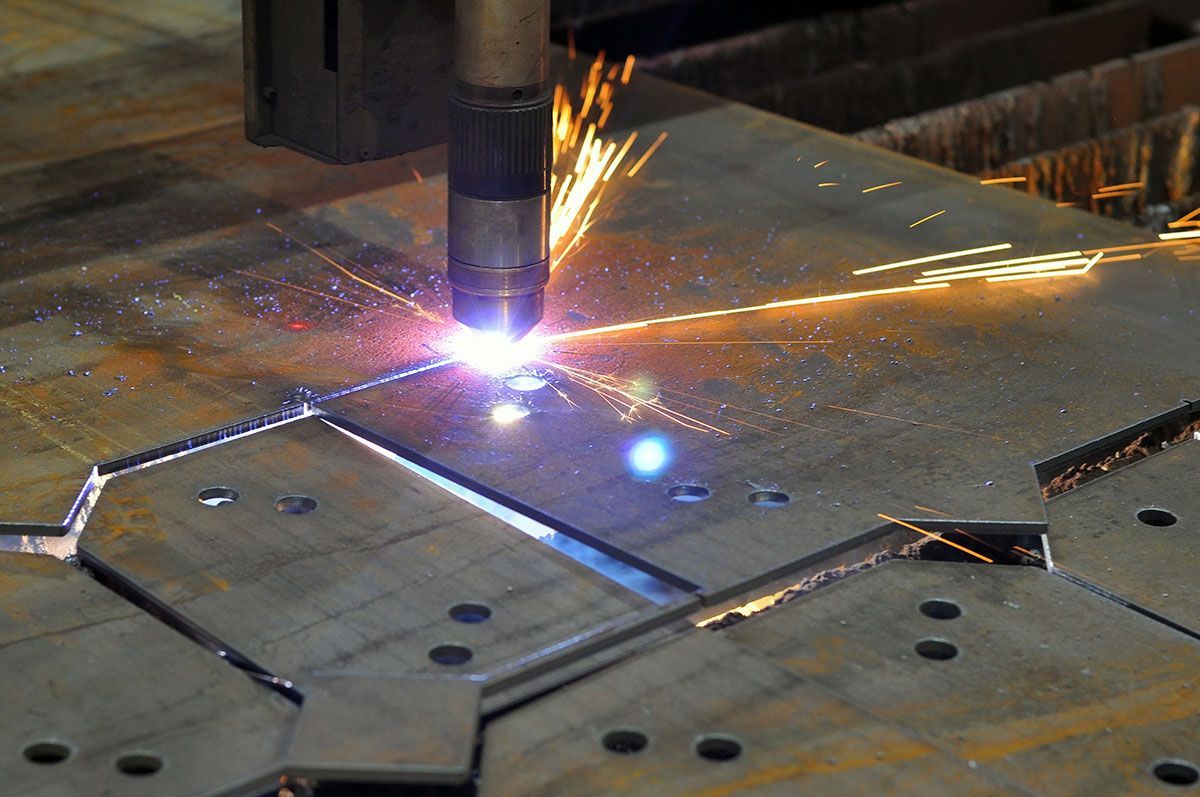

Have you ever wondered why stainless steel projects often demand far more precision than other metals? From architectural frameworks to industrial piping, the strength and appearance of stainless steel rely heavily on the application of specialised welding techniques.

This is why choosing expert welding services in Malaysia can make all the difference—not just in durability, but also in long-term performance. With the right expertise, every weld not only strengthens the structure but also preserves the material’s resistance to thermal stress, mechanical load, and corrosion.

Keep reading to explore how important expert welding services are when handling stainless steel, especially in high-demand sectors.

Why Stainless Steel Welding Demands Precision

Stainless steel may look like an ordinary alloy, but it is highly sensitive during the welding process. Small mistakes can cause warping, corrosion, or loss of strength, which could compromise an entire project or product.

To prevent these issues, expert welders consider factors such as alloy composition, thickness, and joint design before striking an arc.

Material Properties That Affect Weld Quality

Stainless steel has low thermal conductivity and a high expansion rate compared to other metals, such as copper and aluminium, making it prone to distortion if not handled correctly. Its protective chromium oxide layer, which provides corrosion resistance, can also be compromised by overheating or contamination during welding.

Experienced professionals adjust techniques based on these material behaviours to maintain structural integrity.

Industry Applications in Malaysia

From oil & gas pipelines to food processing equipment, stainless steel welding plays a role in nearly every industrial sector in Malaysia. The construction of high-rise buildings, pharmaceutical machinery, and marine components also depends on precise welds that can withstand regional environmental challenges such as humidity and salt exposure.

Best Practices for High-Quality Stainless Steel Welds

Delivering a flawless stainless steel weld isn’t about speed—it’s about following proven processes at every step. By using best practices, expert welders ensure consistent quality and extend the service life of welded structures.

Adhering to these protocols is essential to follow for achieving welds that are both strong and reliable, no matter the project. Let’s explore each step in detail below.

Preparing Materials for Weld Integrity

Surface preparation is critical. Stainless steel must be cleaned of dirt, oil, and oxide layers before welding to ensure a clean weld. Proper edge preparation ensures stronger joints and reduces the chance of contamination.

Selecting the Right Welding Technique

Different welding methods—such as Tungsten Inert Gas (TIG) welding, spot welding, or Metal Inert Gas (MIG) welding—are selected based on the thickness of the material and the application. TIG welding is often preferred for stainless steel due to its control and fine precision, especially on thinner sheets.

Controlling Heat and Preventing Distortion

Heat input management is essential to prevent warping. Welders use techniques such as intermittent welding, back-stepping, or applying chill bars to distribute heat more evenly. This preserves both alignment and strength.

Matching Filler Metals and Shielding Gas

Using the correct filler metals ensures compatibility with the base material, reducing the risk of corrosion. Shielding gases, such as argon or carbon dioxide, protect the weld from the atmosphere, ensuring a clean and strong bond.

Post-Weld Finishing and Inspection

After welding, finishing processes such as grinding, passivation, or polishing restore corrosion resistance and improve surface aesthetics. Rigorous inspection ensures compliance with global weld quality benchmarks.

Looking to ensure your stainless steel projects meet the highest weld quality standards?

Consult with an expert welder today for tailored technical guidance.

How Welding Services Improve Project Outcomes

Engaging expert welding services in Malaysia provides more than just strong welds—it enhances project efficiency, durability, and flexibility across industries. With professional techniques and strict adherence to standards, welding becomes a driver of operational reliability and long-term performance.

Faster Turnaround and Cost Efficiency

Experienced welders utilise advanced equipment and processes that streamline projects, minimise rework, and reduce material costs. This helps businesses meet strict deadlines without compromising quality.

Reliable Strength and Corrosion Resistance

High-quality stainless steel welding ensures components can withstand Malaysia’s humid, high-temperature environment. Proper welds prevent early corrosion and reduce long-term maintenance costs.

Support for Heavy-Duty and Custom Applications

From massive industrial tanks to specialised stainless steel fittings, professional welding services offer solutions tailored to the unique demands of each project. This flexibility is critical for industries such as oil & gas, marine, and construction.

Secure Welding Services in Malaysia from Choong Ngai Engineering

For businesses seeking dependable welding services in Malaysia, Choong Ngai Engineering delivers expertise you can trust. With years of specialisation in stainless steel and other metal works, they are known for precision craftsmanship, technical competence, and reliable service.

Whether your project requires corrosion-resistant joints, heavy-duty structural support, or custom stainless steel fabrication, we provide welding solutions that ensure strength, durability, and long-term value.

Contact us today and let us weld your stainless steel project together!