Metal Skimming: 5 Proven Techniques for Better Efficiency

Every minute of downtime and every defective part eats into margins. The quality of any finished product is only as strong as the foundation beneath it. Metal skimming sits at that foundation as a critical part of surface preparation and metal repair.

In this article, discover why skimming is essential, review 5 proven techniques, and see the measurable results that reliable skimming brings to foundries and fabrication shops across Malaysia.

Why Metal Skimming Matters

Maintaining consistent quality while controlling costs is a daily challenge. Impurities and surface contamination drive rework, disrupt schedules and inflate consumable usage. Mastering the right skimming methods addresses these issues at the source.

Improves Surface Prep and Material Purity

A clean surface is non-negotiable for a strong bond. Whether preparing a weld, applying a protective coating or pouring a new cast, slag, oxides, and foreign matter will compromise results. Effective skimming removes these risks and raises material purity in castings, creating a reliable base for all subsequent steps.

- Creates a pristine surface for welds, ensuring a stronger, more reliable joint

- Guarantees optimal adhesion for industrial coatings, extending their protective lifespan

- Boosts material purity in castings, preventing internal defects and inclusions

Delivers Long-Term Durability and Cost Savings

Early failures cause unplanned downtime, emergency repairs and safety concerns. By eliminating micro-defects and weak interfaces, efficient metal skimming extends service life and stabilises performance. That reduces the total cost of ownership through lower scrap, less labour on rework and smoother scheduling.

- Reduces the risk of premature component failure by eliminating impurity-related weaknesses

- Extends the service life of critical assets, lowering your total cost of ownership

- Minimises unplanned downtime and emergency repairs, improving plant reliability

- Cuts down on material waste and labour costs by reducing the need for rework.

Rising rework from inclusions, pinholes, or adhesion failures? Reduce defects at the source.

Get in touch today for a skimming health check and cost-saving recommendations.

The 5 Proven Techniques for Enhancing Efficiency

These techniques reduce waste, stabilise throughput, and protect delivery dates across melting, surface preparation, fabrication, protection, and repair. Applied together, they raise first-pass yield, extend service life, and keep quality consistent from batch to batch.

1. Molten Impurity Removal – Reduces Slag & Oxides

Slag and oxides rise to the top of a molten bath. If they stay, they harden inside the casting and weaken it. The surface is skimmed while the metal is still hot at above pouring temperature. A refractory scoop or rotary skimmer collects the dross in one steady pass. The hot waste is then put into covered steel bins so it cannot re-oxidise. Cleaner metal produces stronger, more reliable castings.

2. Surface Debris Clearing – Preps for Coatings & Diagnostics

Before welding, coating or inspection, every trace of loosened scale, oxide or paint must go. Abrasive blast media, wire wheels or needle scalers create a fresh profile while leaving the base metal intact. A contaminant-free surface promotes uniform coating thickness, secure adhesion and accurate non-destructive testing, avoiding premature failures that stem from trapped rust or solvent residue.

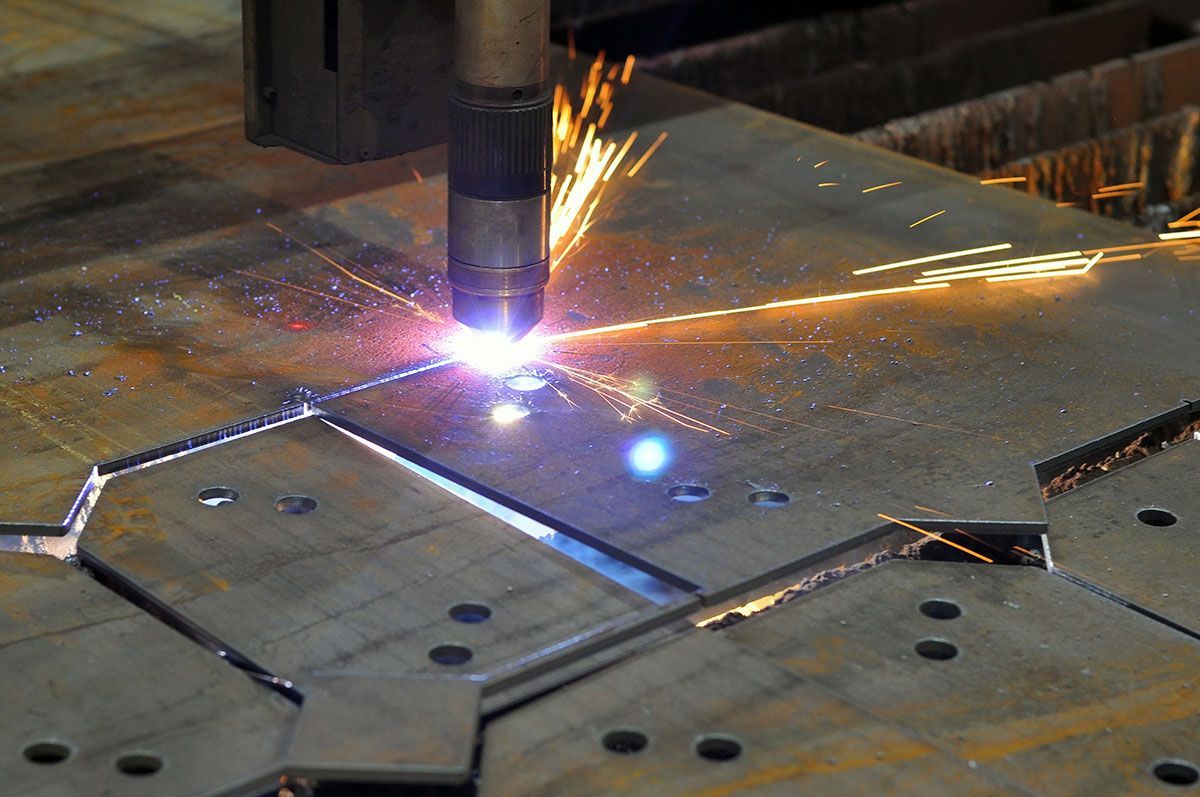

3. Weld & Fabrication Support – Restores Structural Strength

A strong weld starts with clean edges. Grind bevels to bright metal, then skim the molten pool between passes with a stainless spoon or flux-coated paddle. This lifts silica and other impurities that cause pores and cracks. Cleaner passes build a solid bead and cut the grinding time after welding.

4. Industrial Coatings – Extends Service Lifespan

Industrial coatings protect metal from heat, chemicals and abrasion, but only if they stick tightly. A slow-turning brush with hard carbide tips scratches tiny peaks and valleys, about 25 microns deep on average, roughly the width of a human hair, into the surface. This texture lets the coating lock on without cutting into the base metal. Removing micro-oxides at the same time prevents the edges from lifting, so the coating stays put for thousands of operating hours.

5. Precision Part Replacement – Custom Metal Repairs

Full part replacement is costly when only a small area is worn. Diamond-impregnated micro-skimmers remove just the damaged metal. A custom-made insert then slots in and blends smoothly with the original surface. This focused repair restores function fast and avoids long downtime.

Results You Can Measure

Introducing proper metal skimming steps does more than tick a box on a procedure sheet. It produces improvements that show up straight away on maintenance logs and quality dashboards. The gains below are among the first to appear once a plant adopts these proven techniques.

Faster Prep Times

With the correct skimming tools and well-trained operators, surface preparation moves quickly. Grinding, cleaning, and change-overs take less time, so repair or coating work begins sooner and equipment returns to service with minimal delay.

Cleaner Repairs and Coatings

When contaminants are removed at the start, welds, castings and protective layers form on a clean, chemically active surface. The finished parts leave quality control with fewer defects, pass inspections on the first attempt and meet regulatory standards without additional touch-ups.

Less Rework, Lower Costs

Completing a job properly the first time limits the need for extra labour, spare materials and overtime energy use. Stronger, longer-lasting repairs reduce the frequency of callbacks and lower overall maintenance spending across the production line.

Refine Your Metal Skimming Workflow with Choong Ngai Engineering

Every defect avoided, every hour saved, and every part that lasts longer begins with the right surface preparation. If you're facing rising rework rates, premature failures, or unpredictable downtime, Choong Ngai Engineering delivers precision skimming solutions that reduce impurity-related breakdowns, extend component lifespan, and stabilise throughput across your line.

Our process-driven approach lowers maintenance costs, improves coating adhesion, and keeps delivery schedules on track—so your operations run smoother, longer, and more reliably.

Contact us today for a free quotation and discover how our expertise in

metal skimming can cut costs and boost uptime across your production line.