Best Industrial Practices in Metal Spray Coating Selection

TL;DR Section:

The right metal spray coating selection prevents corrosion, wear, and heat damage that cause costly downtime. This guide compares thermal spray technologies and outlines proven best practices so you can confidently specify coatings that maximise equipment performance and lifespan.

Harsh operating conditions can quickly damage metal components—wear, corrosion, and heat buildup all add up. Thermal spray coatings help maintain structural integrity and performance, improving service life even in aggressive industrial processes.

This article explains key performance factors, compares common coating technologies, and outlines best practices for surface preparation and quality assurance. It provides clear, practical insights to guide metal spray coating selection and project management, ensuring durable, cost-efficient protection.

Whether applied to pump shafts, turbine components, automotive parts, or structural steel, the right coating solution can significantly extend equipment lifespan and reliability.

Guide to Selecting Industrial Metal Coating for Industrial Projects

Industrial environments differ widely—from chemical processing plants to high-speed automotive production—and each setting exposes metal surfaces to different degradation risks.

When evaluating coating options, align performance characteristics with operational demands, recognised Malaysian standards (e.g., JSM, SIRIM QAS), and long-term maintenance strategies.

| Selection Factor | Why It Matters | What to Identify |

| Operating Environment | Coatings react differently to heat, chemicals, or abrasion | Exposure to temperature, humidity, and corrosive media |

| Component Function | Rotating or sliding surfaces require different coating hardness | Friction load, thermal stability, and impact |

| Base Material Properties | Ensures strong adhesion and prevents delamination | Compatibility with steel, aluminium, cast iron |

| Thickness Tolerance | Over-build may affect fit or mechanical movement | Match to coating thickness standards |

| Maintenance & Downtime Planning | Ensures budget and operational predictability | Expected service life vs repair costs |

A structured coating selection process reduces the risk of premature failure and rework.

Matching Metal Spray Coating Types to Industry Needs

Different industries push metal components under different stress conditions. Matching the coating to the primary failure risk leads to safer, longer-lasting performance:

- Offshore Pump Shafts: Require high corrosion resistance and a dense barrier layer to prevent pitting and rust in saltwater or chemical environments.

- Automotive Engine Parts: Benefit from hard, wear-resistant coatings that minimise friction and preserve machining tolerances under rapid cycling.

- Food & Pharmaceutical Processing Rollers: Need hygienic, smooth coatings with low porosity to prevent contamination buildup during cleaning cycles.

- Gas Turbine Blades: Rely on coatings that resist extreme heat and particulate erosion in power generation operations.

- Cement & Mining Conveyor Rollers: Require coatings engineered to withstand constant abrasive wear from dust, grit, and conveyed materials.

By assessing how and where each component fails, engineers can

specify a coating system tailored to operational risksrather than applying a generic solution.

Exploring Thermal Spray Coating Types and Applications

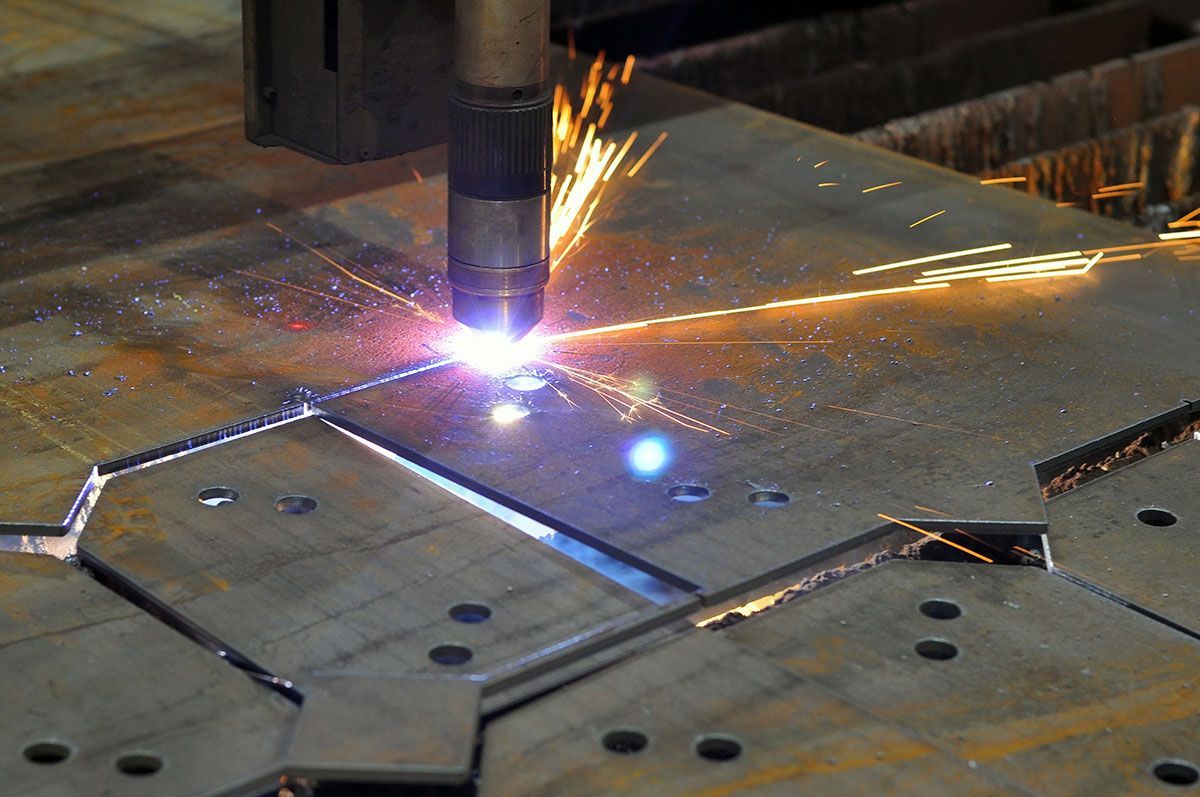

In metal spray coating, thermal spray methods apply molten or semi-molten coating materials to create dense protective layers. Comparable categories include:

Flame, Plasma, HVOF, and Arc Spray

Each thermal spray method offers different strengths—here’s a practical comparison to help engineering teams match technology to performance needs.

| Spray Method | Key Strengths | Best For | Notes |

| Flame Spray | Flexible and economical | General maintenance, restoration work | Suitable for on-site application |

| Plasma Spray | High-temperature process for strong adhesion | Extreme heat applications such as aerospace | Enables ceramic coatings |

| HVOF (High-Velocity Oxy-Fuel) | Dense, hard coatings with low porosity | High-wear and corrosion environments | Extends component service life |

| Arc Spray | Efficient for larger areas | Marine and structural steel | Often requires post-machining for accuracy |

Benefits of Metal Spray Coating for Industrial Machinery

Choosing a high-performance coating contributes to:

- Longer equipment lifespan

- Reduced emergency maintenance

- Higher uptime and output reliability

- Improved performance under heat, friction, or harsh exposure.

Industries such as oil & gas, power, heavy machinery, and automotive rely on coatings as a proactive durability strategy rather than a remedial fix.

Cost Efficiency and Extended Service Life

What appears more expensive upfront typically becomes the most economical long-term option. Benefits include:

- Fewer replacements of high-value parts

- More predictable maintenance schedules

- Reduced machinery stoppages

- Optimised operational performance over years, not months.

Recent studies note that

HVOF coatings multiply parts’ operational lifespan by resisting wear and corrosion at the same time.

Best Practices for Successful Coating Projects

Coating performance depends not just on the material—but also the method, environment, and stringent process controls behind application. Implementing rigorous

process control and testing protocols helps uphold metal coating quality throughout every stage of the project.

Surface Preparation and Quality Assurance

To prevent premature failure, ensure:

- Cleaning and degreasing before any blasting

- Abrasive blasting to achieve proper surface roughness

- Adhesion strength testing aligned with industry standards

- Coating thickness measurement based on specifications

- Porosity and hardness checks for coating reliability.

Following QA frameworks aligned with SIRIM QAS International and CIDB Malaysia strengthens compliance and safety outcomes.

Partnering with Experienced Providers

An experienced metal spray coating partner should provide:

- Technical guidance to match material to wear conditions

- Adherence to recognised safety and quality certifications

- In-house machining and finishing capability

- Full documentation to support traceability and inspection.

Think of the provider as a co-engineering collaborator, not only a service vendor.

Work with Choong Ngai Engineering for Expert Metal Spray Coating Services

If you need guidance on selecting the most suitable metal spray coating for industrial equipment, work with a metal fabrication and coating provider in Malaysia known for durable, cost-effective solutions here in Choong Ngai Engineering.

At Choong Ngai Engineering, our team supports coating selection, fabrication requirements, machining accuracy, and quality verification based on your industry’s operational risks and standards.

Contact us today for tailored guidance and technical support to ensure your machinery investments deliver lasting performance and operational savings.