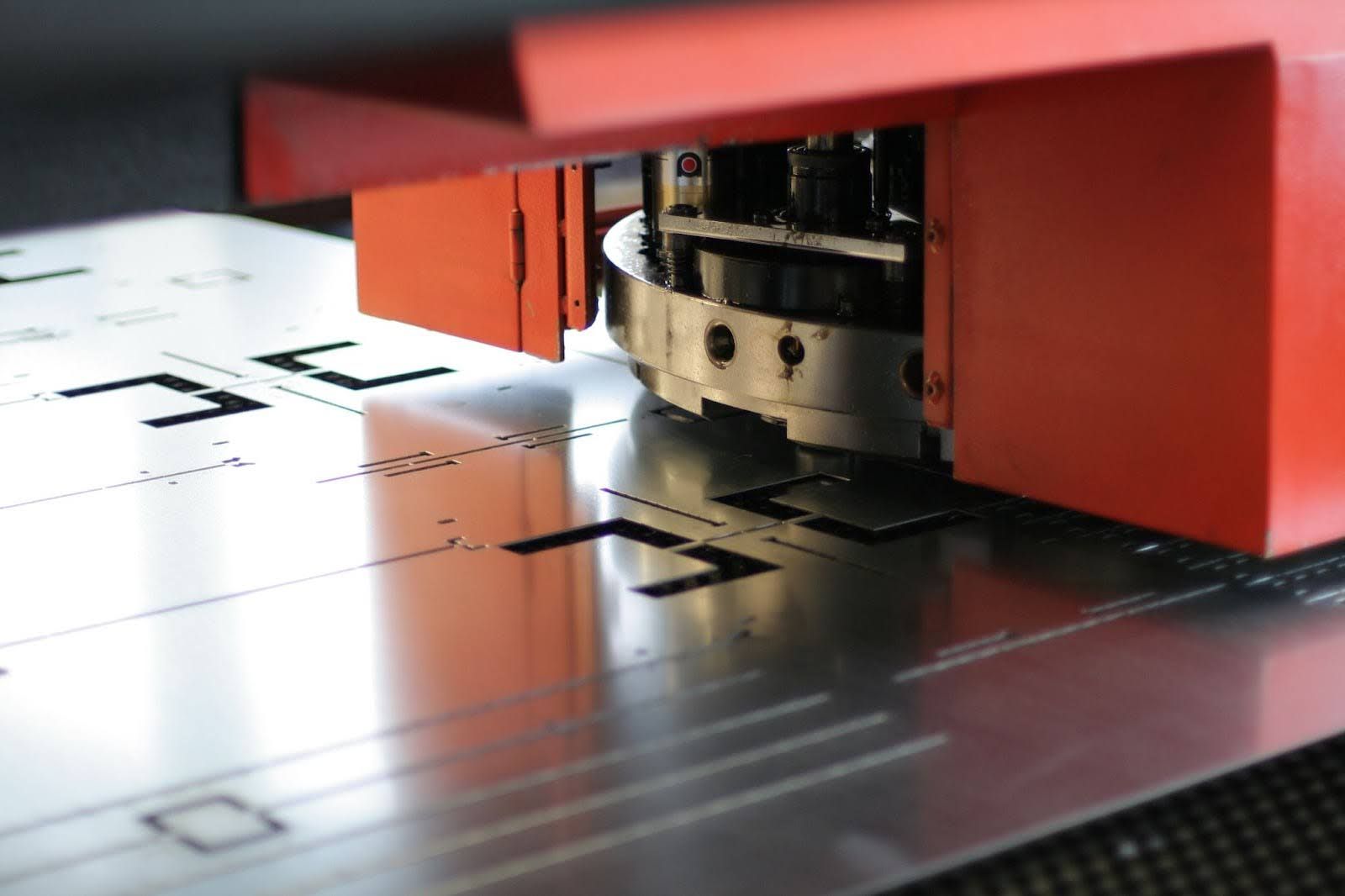

Exploring Metal Stamping and Their Benefits

Metal stamping is an advanced and widely utilised manufacturing process that has come a long way since its beginnings in coin-making during the 7th century. It’s used to create components for various industries such as automotive, electronics, etc., while also being able to save time and money through efficiency while ensuring precision parts of high quality are delivered.

In this blog post, we’ll cover all aspects of metal stamping, including its many methods and machines involved in the process, and discuss its advantages when employed.

What Is Metal Stamping?

Metal stamping is a process that has been around since the seventh century when it was originally used to make coins. Today, metal stamping dies are employed to create shapes and patterns on sheet metal with high accuracy and efficiency for various industries.

The advantages of this manufacturing method include:

- Low cost

- Versatility

- Rapid production cycles

- Precision results in its formation

Unfortunately, certain types of metals cannot be effectively shaped using this technique, which should be taken into account by users considering such an approach.

Die-stamping techniques include progressive die stamping (for mass-producing parts) and transfer punching, where punches remove material from one area at once while transferring them simultaneously onto another piece.

Four-slide equipment or multi-slide presses allow complex geometries and intricate designs, among other applications. At the same time, fine blanking can deliver precise cutting dimensions due to specialised tool designs especially suited for softer materials like aluminium alloys.

These technologies bring unique benefits depending on requirements and/or industry needs, making them ideal choices based on those parameters.

The Various Types Of Metal Stamping Process

Metal stamping encompasses a range of techniques, each with distinct benefits and functions. Progressive die, transfer die, four-slide, and fine blanking are all variations commonly used in the metal manufacturing industry, and they provide diverse solutions for specific projects.

Progressive Die Stamping

Progressive die stamping is a popular and efficient method which produces multiple parts from one single operation, resulting in faster production times as well as reduced costs. Many different industries take advantage of this process, such as:

- Automotive components

- Electronics

- Electrical

In addition, this process is used for the manufacture of items like medical devices, automobiles and plumbing supplies, to name only a few – using progressive stamping dies with metals including:

- Stainless steel

- Copper

- Brass

- Bronze

- Aluminium

- Titanium

All of which provide tight tolerances with high-precision output results.

The advantages that come along are plentiful, ranging from improved rate and efficacy of manufacturing down to minimal scrap waste whilst remaining cost-effective plus accuracy when executing complex geometries and desired shape, making it ideal for high volumes of mass production overall.

Yet there are situations where particular kinds of metal might not be suitable for die stamping, so exploring the pros and cons is paramount before embarking on any project.

Transfer Die Stamping

Transfer die stamping is the preferred process for producing more intricate and sizable components such as:

- Shells

- Frames

- Tubes

- Structural parts

This metal stamping method offers many advantages, like faster production speed and greater accuracy due to utilising well-defined dies during manufacturing along with control gained from servo technology.

To improve precision when stamping compared with other processes using a strip or coil of material – allowing each part to be separated from the metal sheet before it experiences operations in multiple stations, transfer die punching will also enable cost effectiveness through increased efficiency in design and materials utilisation.

Four-Slide Stamping

Multi-slide metal stamping is a metalworking process performed on a horizontal press equipped with tools that are regulated by cams. The use of this technology allows forming metals such as aluminium, brass, bronze and steel into intricate shapes containing bend radii exceeding 90°.

This method has been proven to offer lower production costs than traditional power presses due to its ability to complete all operations required for transforming sheet metal from start to completion.

The multi-slide metal stamping technique is appropriate when fabricating various products like complex springs or other metallic components made out of materials including but not limited to the following:

- Nickel

- Titanium

- Copper stainless steel

- Zinc

- Aluminium

Hence, it is a highly versatile operation granting superior bends within the product’s form over any alternative manufacturing procedures.

Fine Blanking Stamping

Fine blanking is a specialised fabrication process used to create precise parts with minimised burrs and smooth edges, as well as complex shapes. This method of metal stamping produces superior accuracy in flatness and edge quality compared to other stamping processes.

It can be applied to various metals, including:

Tool steel up to 0.625 inches thick- Flat sheet metal

- Heavy metals (bevels, gear plates for multiple gear sets, etc., cams or seat adjusters)

All without needing post-processing for the clean sheared surface it yields once complete.

Different Types Of Machines In The Metal Stamping Industry

Metal stamping machines, used to produce metal parts efficiently, come in two forms: mechanical or hydraulic. Each type provides different advantages and functionalities to assist with this manufacturing. Understanding these variations better helps unlock their capabilities.

Mechanical

Mechanical metal stamping machines are renowned for their accuracy and speed, making them a great option for mass production. By employing flywheel drives, these machines can undertake several metal forming techniques with ease:

- Piercing

- Blanking

- Bending

- Shallow drawing

With the assistance of a motor that drives the flywheel, which stores kinetic energy, two types of press machine models become accessible: type presses and closed-type presses, which provide various capabilities depending on needs.

There are certain uses, such as creating components for vending apparatus or fabricating everyday items from food cans to alkaline batteries, where mechanical metal stamping systems perform exceptionally well due to their rapid speeds in terms of strokes per minute, enabling greater volumes without delay nor variation in product, quality – particularly important when producing complex shapes through metal forming processes.

Its reliability and efficiency make it an attractive choice when quantity slightly overpowers quality but maintains precision throughout each procedure.

Hydraulic

Hydraulic metal stamping machines are able to provide the high level of force and precision needed for metal stamping operations such as:

- Deep drawing

- Blanking

- Piercing

- Forming

They offer more control than other types of machines due to components which generate the required pressure when activated, like a hydraulic system featuring the following automotive parts:

- Pumps

- Valves

- Cylinders

As an added advantage, these machines can be used with a wide range of materials, including:

- Steel

- Aluminium

- Copper

It is especially useful when hard or thick metals need shaping into specific designs or patterns.

Sheet Metal Stamping Advantages

Metal stamping offers many advantages for makers and organisations alike, including cost efficiency, accuracy in fabrication, and versatility. It is known as one of the quickest production processes for metal products. These positives are detailed below.

High precision is an important benefit that this method provides, owing mainly to its automated process with minimal human intervention, thus allowing manufacturers no room for errors or mistakes which could result from manual labour.

Cost-Effectiveness

Metal stamping is an effective process for manufacturing complex components at a lower cost due to reduced labour, machine usage, and secondary costs. Automating the metal stamping system leads to less engineering effort and time, thus providing great savings in terms of cost.

When compared with other processes used for shaping metals, this technique provides excellent quality results more quickly while maintaining accuracy—all of which makes it a much better option that brings financial gains, too.

High Precision and Accuracy

Metal stamping ensures high precision and accuracy due to advanced technology inspection systems that verify the consistent quality of the parts across all. These inspection mechanisms include:

- Visual checks

- Statistical Process Control Systems (SPC)

- In-die sensors

- Optical vision systems

Consistent part quality helps minimise variations or defects during production, thereby boosting accurate metal stamping performance. Stringent criteria are met in the specifications and tolerances for stamped components.

The result is an improved final product when it comes to reliability and overall quality associated with die-stamped metal pieces through precise /high accuracy levels achieved using this procedure. High-grade machine tools, along with robust controls installed on presses, adhere to certain tight parameters, adding assurance in terms of dimensional correctness, thus securing a successful result from the start to the end!

Versatility and Flexibility

Metal stamping is a valuable technology for various industries due to its versatility and flexibility. This enables manufacturers to form complex shapes from metal through processes quickly like:

- Stretching

- Bending

- Curling

- Embossing

Consequently, this technique plays an essential role in producing components related to vehicles, construction activities or electronics at large volumes without compromising the accuracy or cost-efficiency of the parts produced by these operations.

The advantages of metal stamping have made it popular within the automotive industry and aerospace engineering projects. At the same time, medical device production also relies heavily on intricate forms developed via these techniques, which may be deployed reliably over long periods, maintaining high-performance levels throughout their useful life cycle.

Speedy Production Process

Metal stamping is a widely used production process that quickly converts sheet metal into various shapes using die and progressive stamping techniques. Producing high volumes of identical parts can dramatically reduce overall production time compared to other processes, such as CNC machining or welding.

Automation and control methods also help increase efficiency through improved speed, reduced labour costs, quick die change systems, etc., making the whole operation faster yet cost-effective.

Frequently Asked Questions

What are the advantages of metal stamping presses?

Metal stamping presses enable businesses to produce large numbers of parts cost-effectively and time-efficiently, boosting productivity. This method's dies usually entail fewer costs and maintenance than other processes, leading to additional savings.

What are the advantages of metal stamping information materials?

Stamping is often utilised in specific industries due to its cost-effectiveness and high precision capabilities, surpassing other processes' standards. It makes production faster with lower die costs than alternative solutions while producing accurate results even on small components, a plus for hazardous areas such as medical devices or aviation equipment.

What industries benefit most from metal stamping?

Metal stamping is an ideal approach in many areas of industry, providing precision manufacturing at a cost-effective price. Sectors such as automotive, aerospace engineering, medical device fabrication and electronics reap this metal process's benefits due to its accuracy and versatility.

How do mechanical and hydraulic stamping machines differ?

Metal stamping machines, both mechanical and hydraulic, are advantageous for production due to their efficiency in speed and precision. The greater control offered by a hydraulic press machine makes it possible to produce more intricate designs than its counterpart.

Looking for a metal bending service in Malaysia? Try Choong Ngai Engineering

If you're looking for metal bending services in Malaysia, visit us at Choong Ngai Engineering today to speak to our experts. We at Choong Ngai Engineering have years of experience and knowledge to answer your doubts or concerns, and we ensure to provide you with the quality solution you're looking for. Call us now!