The 7 Types Of Bearings And Their Applications

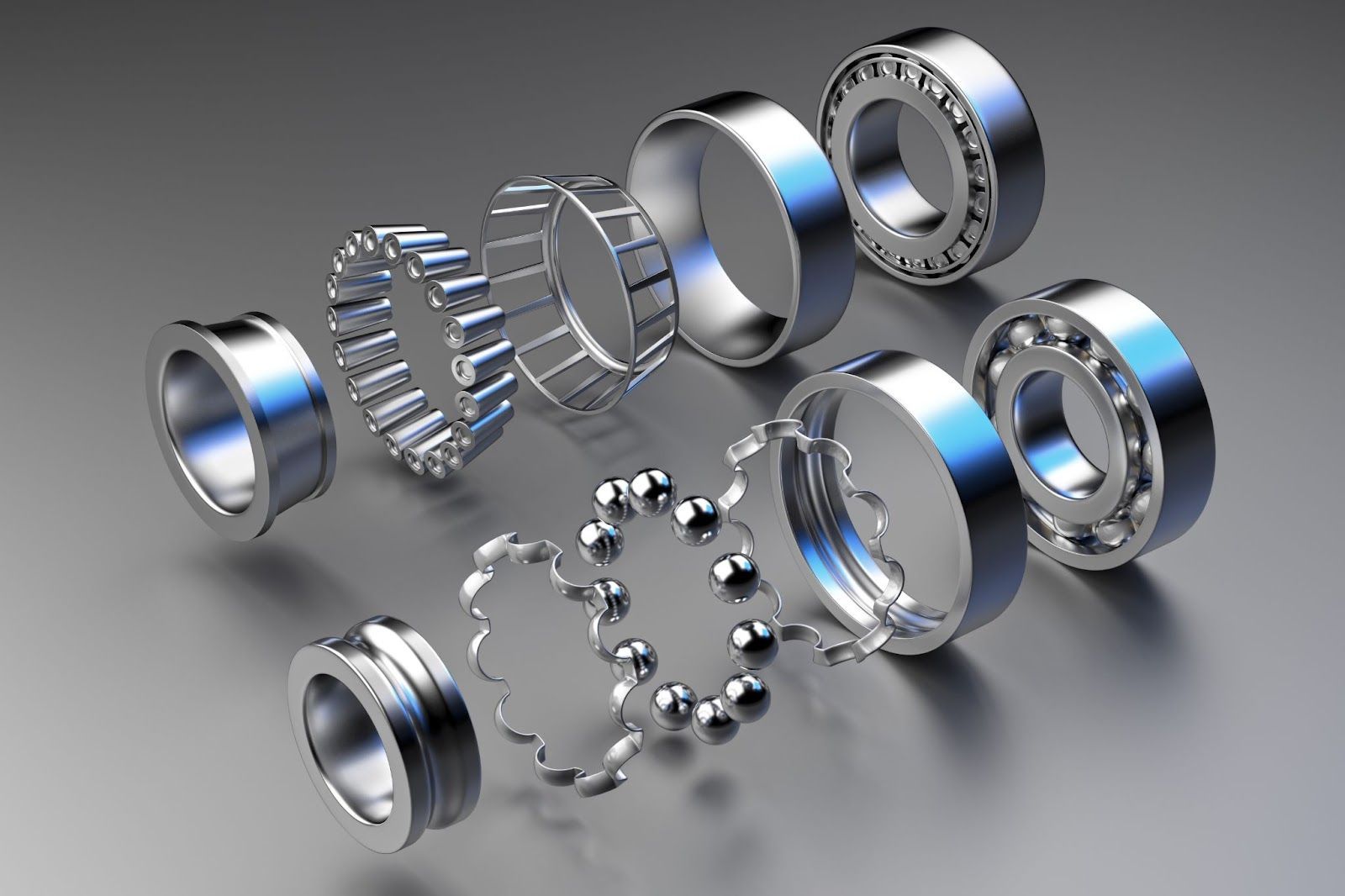

Did you know that most household equipment, such as a refrigerator or vacuum cleaner requires bearing to function? Bearings are parts that stabilise and lower the coefficient of friction of loads. Another way to put it is that when other components on the shaft move, it helps maintain the shaft's fixed centre while lowering the friction coefficient during power transmission.

In today's mechanical machinery, including automobiles, aeroplanes and electric generators, bearings play a crucial role. Its primary duty is to maintain the rotating mechanical body while the equipment is being transmitted, lowering the mechanical load's friction coefficient. With that being said, let's take a closer look at the different types of bearing and their uses.

Thrust Needle Roller Bearings

A subcategory of cylindrical roller bearings designed to manage and maintain higher radial loads is the thrust needle roller bearings. Due to their durability and reliability, these types of roller bearings are used for joints for maintenance-related reasons.

The thrust needle roller bearing is one of the most recently developed roller bearings, featuring a greater number of longer and thinner cylinders within the bearing's raceway. It was created in this way to lessen friction under heavier radial loads and lower the possibility of misalignment.

Besides that, the thrust needle roller bearing's potential to handle high radial loads in mechanical functions is enhanced by its ability to shrink in size and carry more elements. To increase thrust loads, this roller bearing includes a single, linear line of rolling elements inside the bearing racetrack.

Despite having a smaller size, the thrust needle roller bearing can play significant roles in several of the same various industrial uses as the cylindrical roller bearing, including:

- Pulley Supports

- Air Compressors

- Transmissions Devices

Four-Point Contact Ball Bearings

Four-point contact ball bearings can carry radial and axial loads in both directions. A single bearing can replace the combination of angular contact ball bearings in front or back. It can support simulated loads with a significant axial load component and pure axial loads. This bearing is resistant to all directions.

When the axial force is applied, one of the contact angles can be generated, ensuring that the ring and ball always make contact with two sides and three points along any contact line. Some examples of equipments that uses four-point contact ball bearings are:

- Automotive chassis and gearboxes.

- Gearboxes for industrial, rail and wind turbine applications.

- Agricultural vehicles and equipment

Thrust Roller Bearings

Thrust roller bearings support axial load-based shafts paired with warp load. However, the warp load cannot exceed 55% of the axial load. When compared to other thrust roller bearings, this bearing offers the following:

- Lower friction coefficient

- Higher speed

- Self-aligning capability

The asymmetrical spherical rollers used in 29000 type bearings have the following characteristics:

- Extended length

- Big diameter

- A large number of rollers

These features can reduce relative sliding while in use between the stick and the raceway. Thrust roller bearings are typically used in equipments that involve rotation, such as:

- Crane hook

- Hydroelectric generator

- Hydraulic pumps

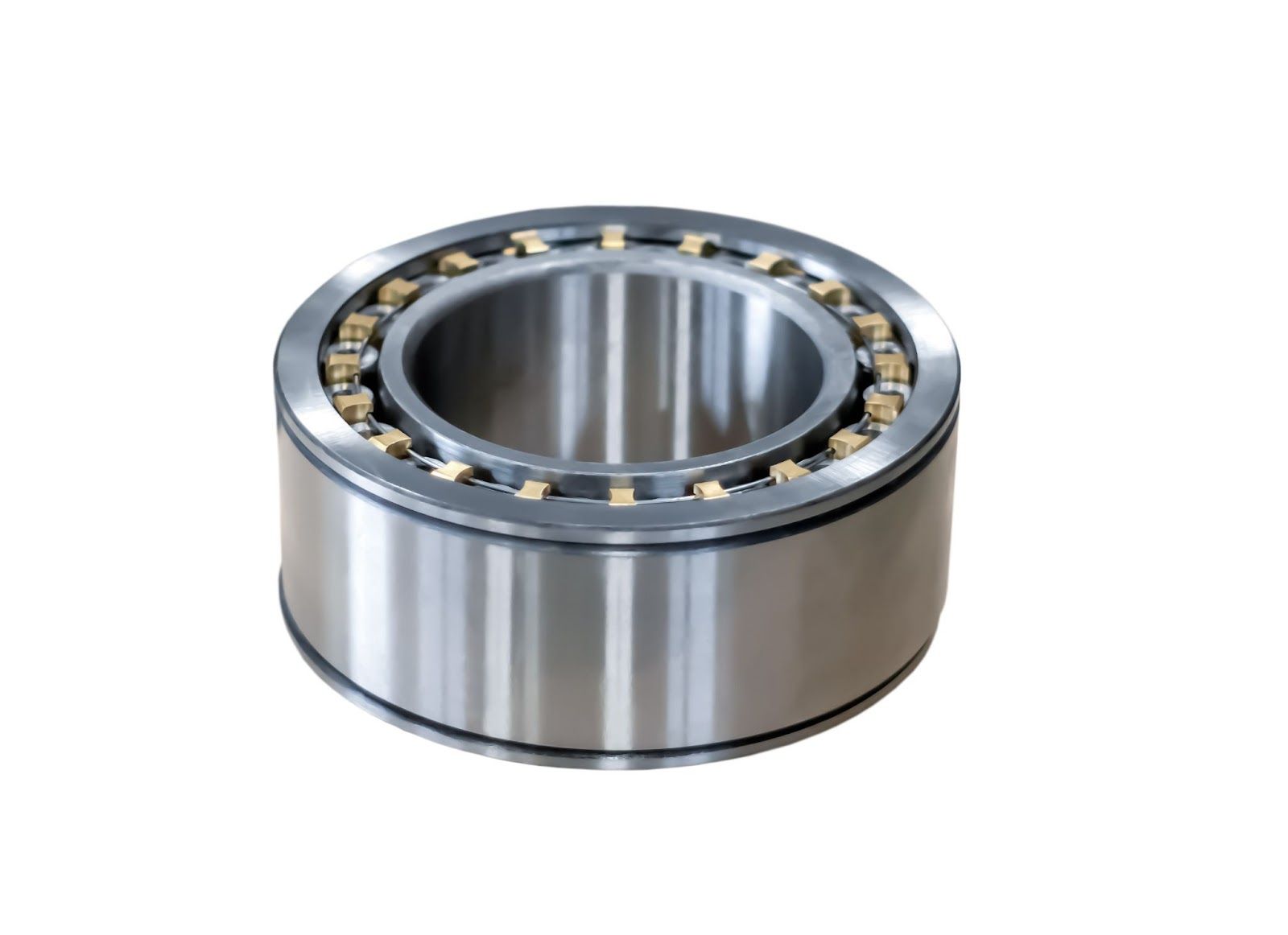

Cylindrical Roller Bearings

Two ribs of a bearing ring are typically used to guide cylindrical roller bearings. Thus, the cage roller and guide ring create an assembly that may be disassembled from the other bearing ring, which is a separable bearing.

This type of bearing is easy to install and uninstall, particularly when the inner and outer rings, as well as the shaft and housing, have a snug fit. These bearings are often exclusively used to support radial loads. Only single-row bearings with ribs on both inner and outer rings can support tiny steady axial loads or high intermittent axial loads.

Outer Spherical Ball Bearing with Seat

The outer spherical ball bearing with seat is made up of an exterior spherical ball bearing featuring seals on both sides and a cast-bearing seat. Furthermore, the outer spherical ball bearing shares the same internal structure as the deep groove ball bearing.

However, its inner ring is more expansive than its outer ring and has a shortened spherical outer surface. As a result, it can automatically align when matched with the concave spherical surface of the bearing seat.

Thrust Tapered Roller Bearings

These bearings have shortened cylindrical rollers. The two ends of each conical surface intersect at a point along the bearing's centre line. Both one-way and two-way bearings can withstand axial loads in only one direction.

Thrust Cylindrical Roller Bearings

Thrust cylindrical roller bearings are made up of cage assemblies and raceway rings in the shape of washers. Due to the convex surfaces used in their processing, cylindrical rollers can withstand unidirectional axial loads and have a uniform pressure distribution with the raceway surface. Both the axial load capacity and the axial stiffness are substantial.

For A Machinery To Function Seamlessly, It Is Vital To Understand The Right Application Of A Bearing

Bearings are small, but they play a crucial role in modern machinery as they help stabilise and lower the friction coefficient of loads. Hence, understanding the different types and proper application of each is essential to boost the performance of machinery.

Looking for high-quality heavy equipment spare parts in Malaysia? Choose Choong Ngai Engineering!

So, if you're looking for a heavy equipment spare parts contractor in Malaysia to help you develop the bearings that you require for your machine, visit us at Choong Ngai Engineering today to speak to our experts. We at Choong Ngai Engineering have years of experience and knowledge to answer your doubts or concerns, and we ensure to provide you with the quality solution you're looking for. Call us now!