Understanding the Art of Plate Rolling

While many are familiar with the more common metal fabrication techniques like bending, welding, and cutting, not many are familiar with plate rolling. Plate rolling is an underrated form of metal fabrication that involves shaping large metal sheets into cylindrical or conical forms.

The art of plate rolling combines both advanced machinery and the skilled hands of experienced technicians, making it a fascinating yet challenging discipline within the world of metalwork. As an essential process in industries like aerospace and construction, plate rolling demands precision and expertise for structural integrity.

If you’re interested in learning more about plate rolling and its significance, look no further. In this article, we explore the nuances of plate rolling to reveal the delicate balance between technology and craftsmanship required to achieve perfection.

What is Plate Rolling?

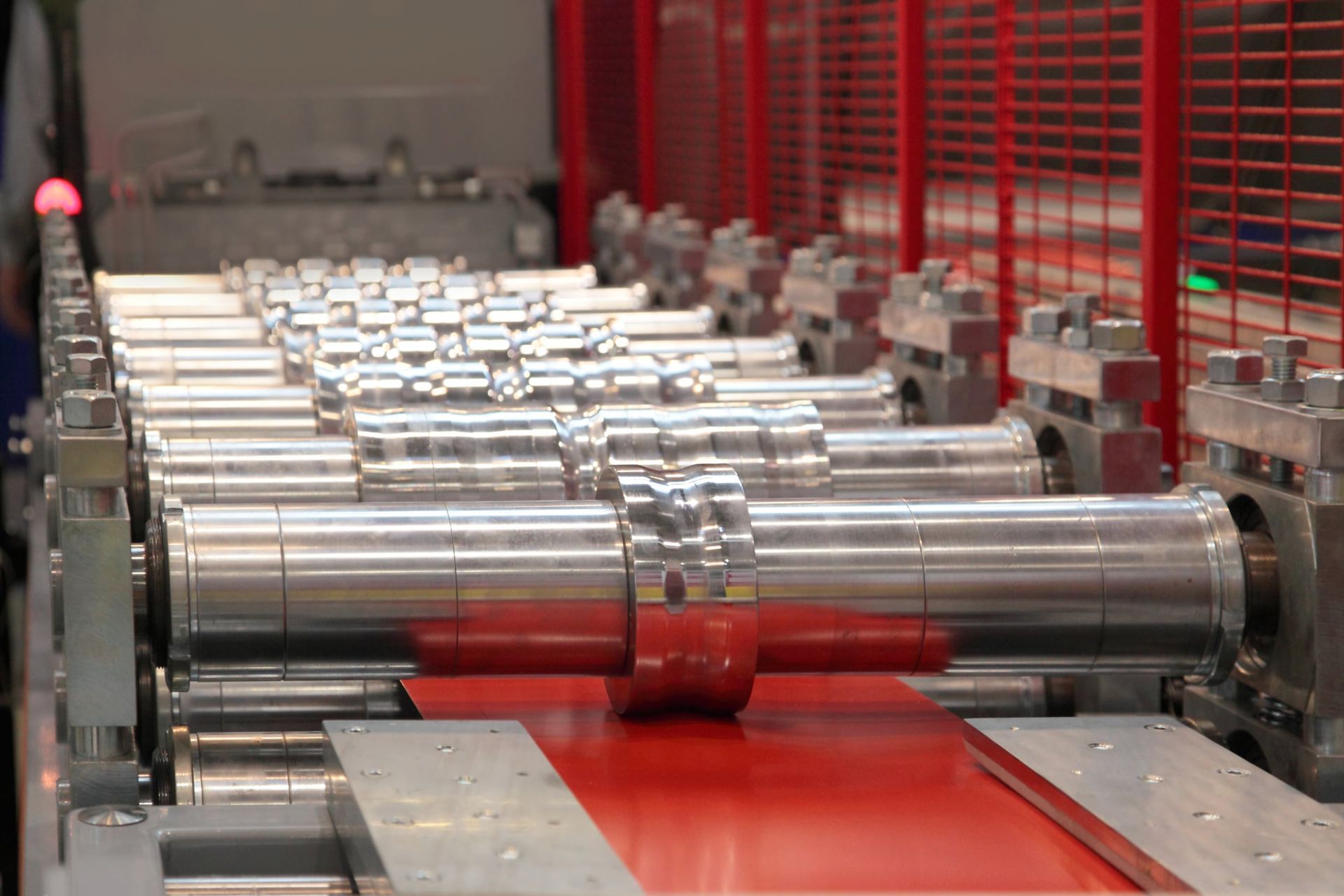

Plate rolling is one of the many techniques in the art of metal fabrication. It works by feeding a large plate of flat sheet metal into a powerful rolling machine with a drive system. Once it is sandwiched between two large rollers, it is then gradually bent and shaped as it passes through, forming a smooth, curved surface that can be tailored to precise specifications.

While this process might require several pass-throughs to get the metal sheet into the desired shape, it ensures uniformity and precision. This makes it ideal for producing high-quality cylindrical and conical components used in various industrial applications.

Unveiling The Applications of Plate Rolling

Plate rolling is used in various industrial applications, ranging from aerospace and shipbuilding to construction and manufacturing. It is commonly used to create pipes, tanks, and other cylindrical structures of different sizes and material thicknesses, regardless of the type of metal.

Whether it’s steel, aluminium, or copper, plate rolling can bend and shape your product’s needs and preferences. Here are some of the most common applications of plate rolling across various industries.

- Oil and Gas Industry: Plate rolling is used to create oil and gas pipelines, which require a consistent diameter for efficient flow of oil and gas.

- Shipbuilding Industry: Plate rolling is useful for creating hulls and tanks in ships, as it creates double-curvature surfaces that other forming processes can’t handle as efficiently.

- Manufacturing Industry: In the manufacturing industry, plate rolling helps create various components, like steel drums, tanks, pipes, and other cylindrical or coned metal components for heavy machinery.

4 Advantages of Plate Rolling

Now that you’ve learned about the intricacies of plate rolling and its applications, let’s learn about what makes them advantageous over other metal fabrication techniques.

Here are the 4 advantages of plate rolling, showcasing how this method enhances various high-stakes industries like aerospace and construction.

Cost-Effective

Plate rolling has a higher initial cost that might hinder others from utilising it for their projects. However, it proves to be cost-effective in the long run due to its ability to produce consistent, high-quality components with minimal waste.

The process’s efficiency reduces the need for additional finishing and rework, ultimately saving time and resources, making it a smart investment for large-scale and high-precision applications. Furthermore, rolled plate structures require minimal maintenance and repairs, which contributes further to its cost-effectiveness.

Versatile

There is no denying that plate rolling is a versatile metal fabrication technique. From simple curved structures to intricate conical forms, it can be shaped to produce a wide range of cylindrical and conical structures, accommodating different sizes and thicknesses of metal sheets.

This adaptability makes it suitable for diverse applications in industries like aerospace, construction, and manufacturing. Moreover, the ability to create custom shapes and designs with precision further enhances its utility and appeal in different ranges across various industries.

Strong and Durable

If you’re worried about plate rolling tampering with your metal sheet’s structural integrity, rest assured! Plate rolling preserves the metal material, ensuring that it remains strong and durable no matter what structure form it takes.

Additionally, this technique distributes stress evenly across the metal, reducing the likelihood of weak points and fractures. The result is a robust, high-quality product suitable for demanding applications in various high-stakes industries.

Accuracy and Consistency

Plate rolling requires a drive system to work, ensuring unparalleled accuracy and consistency in forming metal sheet structures. The controlled movement of the rollers guarantees uniform bending throughout the length of the plate, minimising errors and ensuring precise dimensions.

Reliability is crucial in industries where structural integrity and exact specifications are paramount, which is why plate rolling proves itself to be a superstar in this field. Plate rolling’s ability to maintain tight tolerances over large surface areas makes it a preferred method for achieving complex shapes with minimal material waste and optimising production efficiency.

Looking for a quality plate rolling service in Malaysia? Choose Choong Ngai Engineering!

If you’re looking for a quality plate rolling service in Malaysia, look no further! Visit us at Choong Ngai Engineering and speak to our experts on our plate rolling service. As experts in the field, we have developed a speciality in offering excellent plate rolling services suitable for a wide range of projects and industries.

Speak to our experts at

Choong Ngai Engineering, and let us help you with any of your doubts and concerns to ensure we provide the best solution you’re looking for.

Call us today!