5 Modern Types of Metal Fabrication Techniques

Metal fabrication has been around for as long as humans have discovered metals. This intricate craft, which started with a method as simple as hammering, has been honed for centuries. What started as a simple technique has now become an essential part of building the world we know today.

From jewellery to skyscrapers, metal fabrication techniques have evolved to do it all. With advancements in technology, these techniques have become more precise, efficient, and versatile, allowing for the creation of complex structures and intricate designs that were once unimaginable.

In this article, we’ll explore the 5 modern types of metal fabrication techniques, showcasing how much the craft has evolved to adapt to modern times. Keep reading to discover how innovative methods and cutting-edge technology are shaping the future of metalworking.

Waterjet Cutting

Waterjet cutting is one of the most innovative metal fabrication techniques in modern times. It’s a technique that uses an industrial machine with a high-pressure stream of water to erode narrow lines within a piece of metal.

Moreover, waterjet cutting can be used for any application, regardless of material and thickness. Whether it’s steel or titanium, it can cut through all, which is especially useful for internal cut-outs. This is because it has a cutting accuracy of ±0.1 to ±0.2mm, perfect for unique and intricate designs.

Laser Cutting

Similar to waterjet cutting, laser cutting is an amazing feat in the metalworking industry. With high-power laser beams harnessed to cut or engrave through metal, it is the pinnacle of precision.

Laser cutting works by vaporising the metal material, where the laser is directed to cut through it to create a cut edge. While it is most prevalent in industries like aerospace, computer electronics, and robotics, it has also been more common among schools, small businesses, and metalworking hobbyists for its efficiency and simplicity.

CNC Machining

When it comes to modern metal fabrication techniques, CNC machining must be mentioned. Computer Numerical Control (CNC) machining is a game-changer in the world of metalworking, thanks to the advancement of automation technology and innovations.

What sets CNC machining apart from other modern metal fabrication techniques is that it is controlled by computer software to create and make parts. It has an unmatched ability to replicate designs and layouts flawlessly and efficiently.

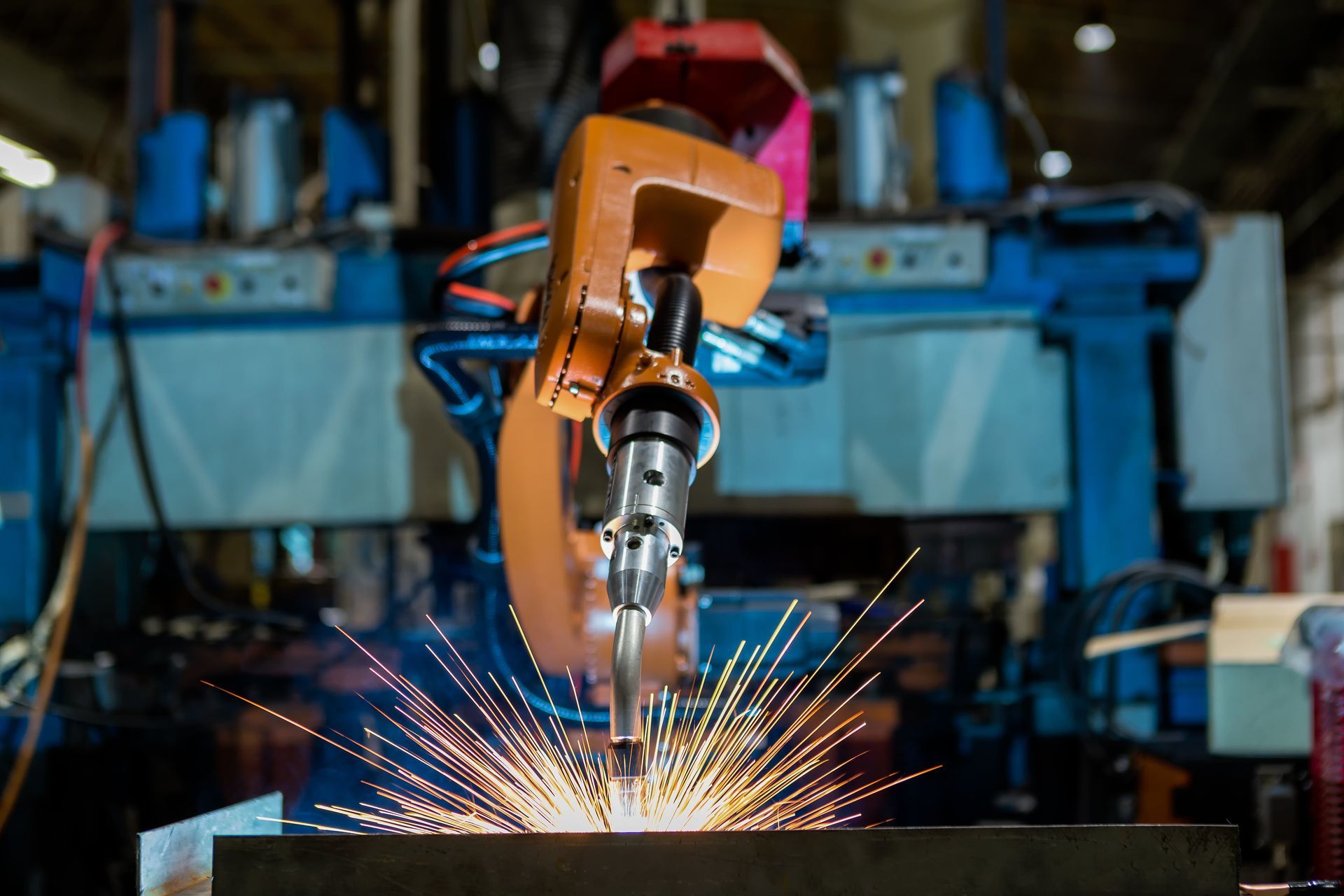

Robotic Welding

Robotic welding is another great feat in the metal fabrication landscape. It’s an automated technique that utilises a special type of industrial robot to weld metal together, especially in heavy industries like automobiles, for accuracy, repeatability, and throughput.

First introduced in the 1960s, these welding robots are often found in assembly lines handling metal materials with specialised devices through different types of programmed motions. As technology advances, robotic welding continues to improve, incorporating AI and machine learning to adapt to various welding tasks and enhance performance.

Shielded Metal Arc Welding

A combination of advanced technology and craftsmanship, shielded metal arc welding is a versatile and widely used metal fabrication technique. It involves using a consumable electrode coated in flux to create an electric arc between the electrode and the base material, effectively melting the metals and allowing them to fuse together.

This modern technique is valued for its simplicity, portability, and ability to weld various types of metals and thicknesses, making it ideal for construction, repair, and maintenance work. Despite its reliance on skilled manual operation, advancements in welding equipment have enhanced precision and efficiency, ensuring high-quality welds in diverse applications.

Looking for a quality metal fabrication service in Malaysia? Choose Choong Ngai Engineering!

Are you looking for a metal fabricator in Malaysia for your metal fabrication needs? Visit us at Choong Ngai Engineering and speak to our experts on metal fabrication. As experts in the field, we provide metalwork services with modern technology that are suitable for a wide range of projects and industries.

Speak to our experts at Choong Ngai Engineering, and let us help you with any of your doubts and concerns to ensure we provide the best solution you’re looking for. Call us today!