Stainless Steel Fabrication: Understanding its Step-by-Step Process

Stainless steel fabrication has existed for over a century, with techniques constantly evolving to meet the demands of various industries. This intricate process transforms raw stainless steel into valuable components, playing a critical role in sectors ranging from construction to healthcare.

Whether crafting architectural marvels or delicate medical instruments, the expertise required in

stainless steel fabrication is immense. In this article, we’ll delve into the step-by-step process of stainless steel fabrication to better understand the intricate techniques and precision involved.

Keep reading to learn more about the step-by-step process of stainless steel fabrication, unveiling the journey from raw material to finished product to reveal the fascinating innovation in stainless steel fabrication.

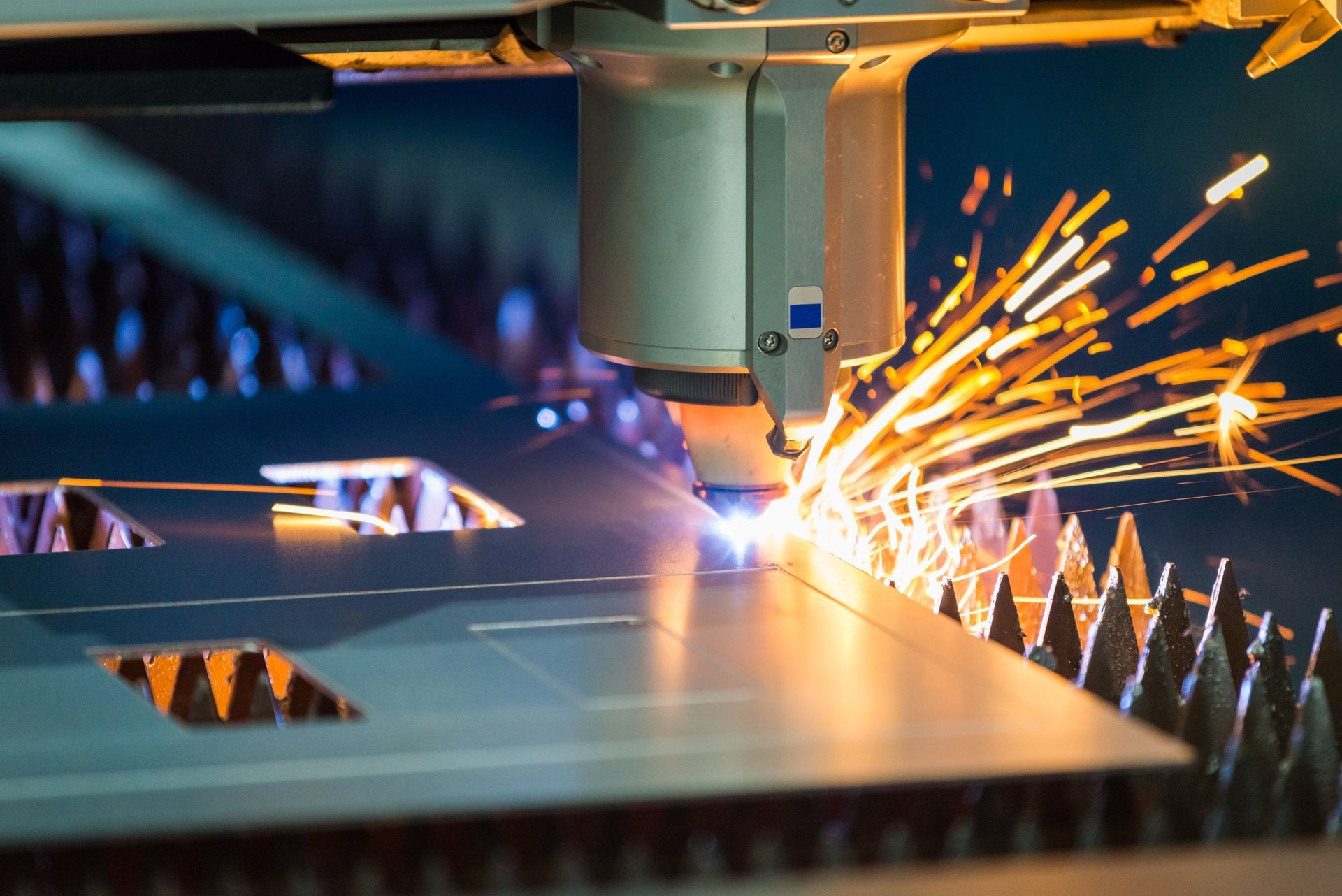

First Step: Cutting

The first step to fabricating stainless steel is cutting. This process is often the first and most critical step because it determines the initial shape and size of the material, ensuring that it meets the precise specifications required for further processing and assembly.

Various methods are used to cut stainless steel, such as laser cutting, waterjet cutting, CNC machining, and more. Each cutting method is used depending on the thickness of the stainless steel sheet or part and the precision it requires.

Without this crucial step in the stainless steel fabrication process, the stages that follow, such as welding, bending, and assembly, would be compromised, leading to potential inaccuracies, increased material waste, and a higher likelihood of defects in the final product.

Second Step: Bending & Forming

Once the stainless steel parts are cut to the desired shape and size, it’s time for the bending and forming process. Stainless steel can be bent and formed into various shapes with specialised tools and machines, making them indispensable in industries like engineering, construction, and manufacturing.

Some of the specialised tools, machines, and techniques involved in the bending process are rolling machines, press brakes, and bending rolls, while the forming process includes pressing, press-forming, and spinning. Each tool is designed to handle different types of bends, forms, and material thicknesses to achieve the desired shape.

Third Step: Welding

Welding is one of the most important steps in the entire process. It joins the cut and formed stainless steel parts together, creating a unified and structurally sound assembly. To join stainless steel parts together, welding uses heat and pressure to melt and fuse the material at the joint, ensuring a strong and durable bond.

For a successful and high-quality outcome, welding has to be done properly with a fabricator or welder with specialised knowledge and experience. This avoids compromising the quality of the stainless steel, ensuring that it maintains its corrosion-resistant, strong, and durable properties to meet industry standards and requirements.

Fourth Step: Finishing

The finishing process looks different for every stainless steel fabrication project, depending on the part’s future use and application. A polished finish might enhance the visual appeal of parts intended for aesthetic applications, while components used in harsh environments might undergo passivation to increase corrosion resistance.

This step is crucial to ensure that the final product meets specific functional and aesthetic standards, enhancing its durability, appearance, and performance for its intended purpose.

Final Step: Quality Inspection

Finally, once everything has been done, from cutting and welding to finishing, don’t forget to do a thorough quality inspection. This is to ensure that whatever stainless steel fabrication project is done, whether it’s rods, pipes, or an art project, meets high-quality standards.

During stainless steel fabrication quality inspection, you might test and verify the mechanical properties through stress and strength tests and chemical properties, ensuring that they meet the recommended standards on corrosion resistance.

Looking for a quality stainless steel fabricator in Malaysia? Choose Choong Ngai Engineering!

If you’re looking for a stainless steel fabricator in Malaysia, head on over to Choong Ngai Engineering! As experts in the field, we provide metalwork services that are suitable for a wide range of stainless steel fabrication projects and industries.

Speak to our experts at Choong Ngai Engineering, and let us help you with any of your doubts and concerns to ensure we provide the best solution you’re looking for.

Call us today!