Common Machine Screws That Are Used In Everyday Lives

The most popular fastener in the world is a screw, distinguished by helical threading around a long shaft. Screws are frequently used to attach two or more solid things together. They provide a quick and straightforward way to connect many solid items.

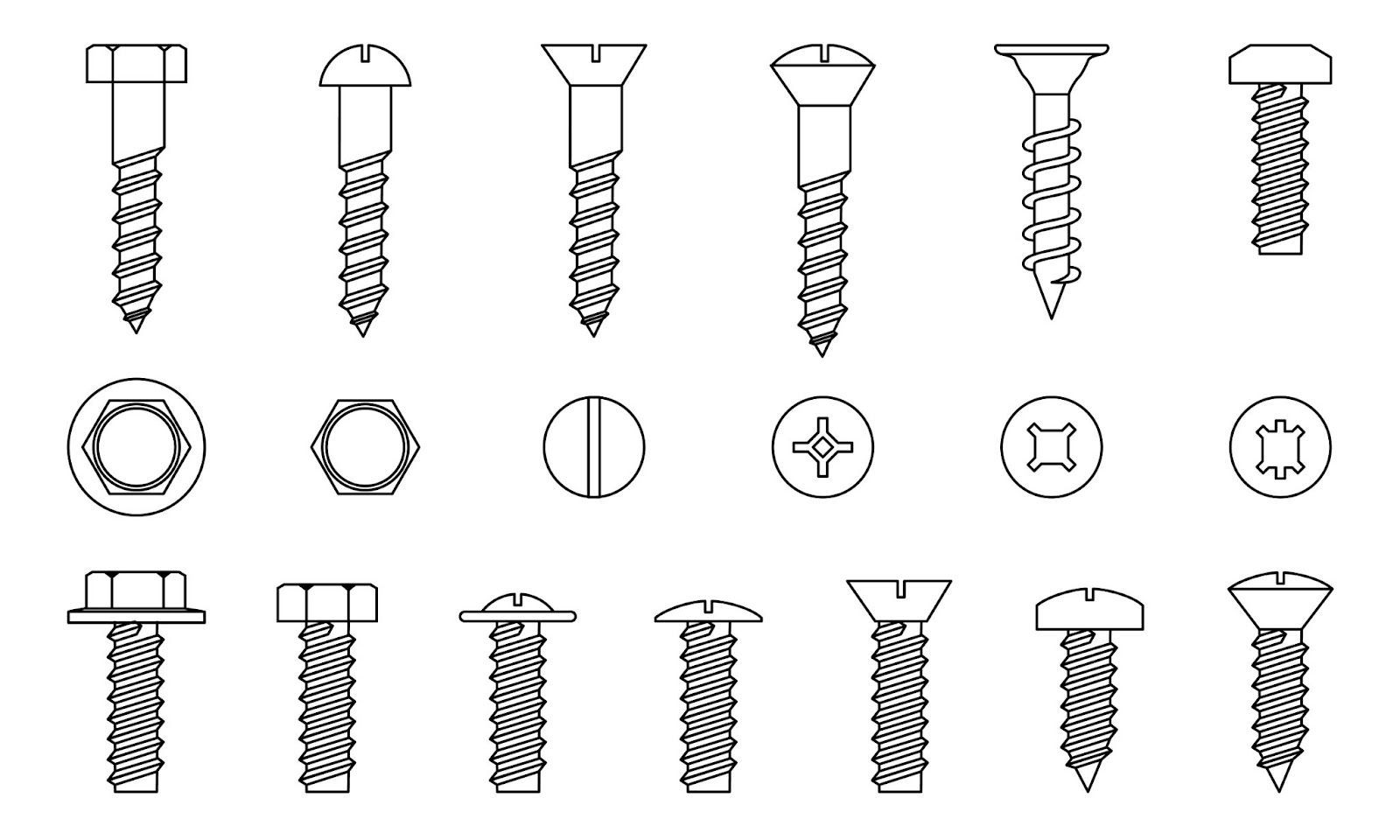

Although all screws have helical threading around a shaft, not all screws are created equal. So let's take a closer look at the various common machine screws used in everyday life.

What Are Machine Screws?

There are wide varieties of screws, bolts, and other fasteners and fixes. Of the wide different varieties of standard fasteners, machine screws are one of the more frequently used items.

Although they are often used, machine screws are not specifically defined. A wide variety of fastener types are referred to as "machine screws." As such, machine screws often come with a variety of head types and can be either coarse- or fine-threaded.

However, machine screws are typically distinguishable from other popular fastener types, such as wood screws, by their physical characteristics and intended use.

What Are The Various Uses Of Machine Screws?

Machine screws are most commonly used to connect metal pieces and panels together. This is a common requirement in all types of industries, including:

- Manufacturing

- Production

- Assembly

- Industrial settings

In other words, machine screws are utilised like any other kind of screw or bolt. Some of the uses of machine screws also include:

- Drilling or tapping into a pre-drilled hole or nut

- Holding down or sandwiching gaskets and membranes

- Used on terminal strips and for a variety of other electrical connections

- Separating and securing components or panels that must be kept at a predetermined distance from one another

The Various Types Of Machine Screws

Machine screws come in a wide range of the following, such as:

- Sizes

- Head types

- Materials

- Thread gradings

This is a list of some of the most common types of machine screws that are easily accessible:

Hex Head Machine Screws

The sort of machine screw that resembles traditional bolts the most is the hex head screw, often known as a set screw. This is mainly because both fasteners' heads are recognisable hexagon shapes with six sides.

Hex head machine screws can sometimes be installed with more torque by using a standard wrench or spanner. Alternatively, they may also feature a drive socket that is recessed into the head, indicating that they are intended to be used with a more conventional screwdriver.

Flat Head Machine Screws

When a fastener needs to be fitted and sit flush with the surface it is being driven into, flathead machine screws are the best option. They provide a tidy and flush surface finish on attached panels and components owing to their flattened top and countersunk underside profiles.

Oval Head Machine Screws

Machine screws with an oval head provide a kind of compromise between flat-headed versions and the more common industrial pan head style.

Oval heads are less obvious because of a curved underside that creates a somewhat countersunk profile, in contrast to pan heads, which stay conspicuously elevated from the surface once driven home. As opposed to flat-head machine screws, they do not countersink as precisely.

Cheese Head Machine Screws

When viewed from above, cheese head screws resemble standard round head screws, but the flat-topped head is cylindrical and has a pronounced depth when viewed from the side. This type is frequently chosen for its added durability and strength.

Various Types of Screwdriver For Machine Screws

Machine screw drive types describe the type of screwdriver tools required to tighten or loosen a certain machine screw from a threaded hole or nut. The following are examples of standard machine screw sockets:

Slot

A popular design that has a single straight socket which spans the machine screw's head and is intended to be fastened with a flathead screwdriver.

Cross or Phillips

Machine screws with a cross drive feature an X-shaped socket in the head, which increases the maximum torque somewhat more than a regular slot drive.

Hex

Machine screws with hexagonal recessed drive sockets in the head typically need to be driven with an Allen wrench or hex driver.

Hexalobular Recess

The socket, which has a six-pointed star form and is frequently referred to as Torx or star drive, can only be driven efficiently with a tool that is also a star drive or Torx.

Getting The Right Type Of Machine Screw Is Vital For Efficiency

Now that we have covered some of the most common machine screws available, picking the right one for your next project will not be as overwhelming as it seems initially. Asking professionals for advice will come in handy as well.

Looking for high-quality machinery spare parts? Visit Choong Ngai Engineering now!

Choong Ngai Engineering is a leading heavy equipment spare parts fabricator in Malaysia. With over 19 years of experience, we are your one-stop solution for all your heavy equipment spare parts needs. Contact us or call us at +6012-2726971 today to get started!