Keys to Selecting the Right Sheet Metal Fabricator

It can be challenging to know who to trust when selecting a sheet metal fabricator. After all, this is a company that will be responsible for manufacturing some of the most critical components of your business. If you're not careful, you could work with a fabricator who is inexperienced or unreliable.

This blog post will discuss the key factors you should consider when selecting a sheet metal fabricator. This guide will help you choose a fabricator best suited for your needs.

Experience

One of the most important factors to consider when selecting a sheet metal fabricator is experience. You want to work with a company with a proven track record of success. Look for a fabricator that has been in business for several years and has experience working with companies in your industry.

Equipment

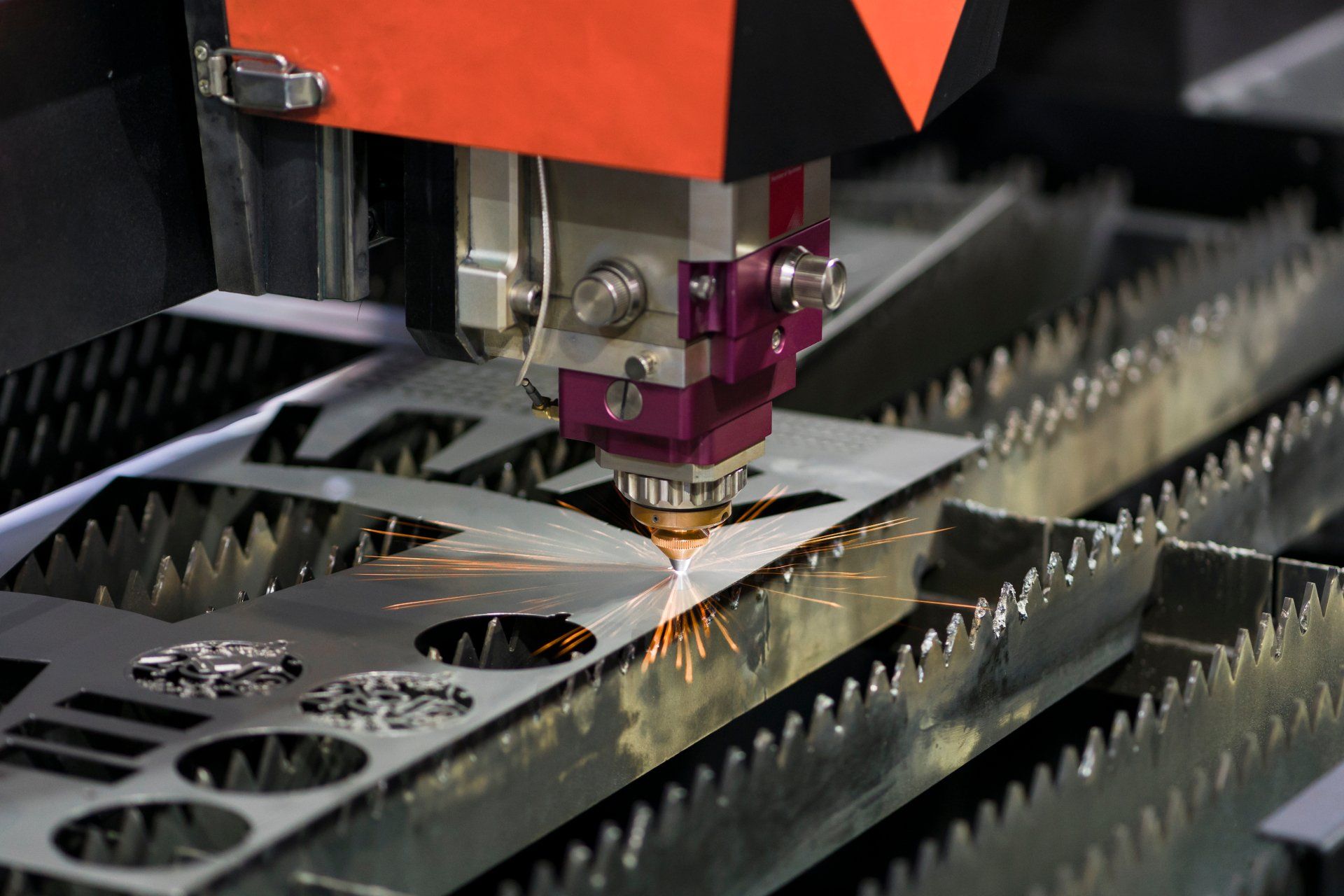

The best sheet metal fabricators use state-of-the-art equipment to ensure that your parts are manufactured to the highest quality standards. Ask about the type of equipment that the fabricator uses and whether they have updated their equipment in recent years.

This is a crucial question because outdated equipment can lead to parts that don't meet your quality standards.

Capabilities

You want to work with a company that can manufacture the types of parts you need. This is because some companies specialize in specific types of features or materials. Make sure that the company you're considering is capable of manufacturing the parts you need before you make a decision.

Availability

It's essential to work with a company that is available when you need them. This means that they should be able to accommodate your production schedule and meet your deadlines. If you're working on a tight timeline, ensure that the fabricator you're considering can fulfill your needs.

Certifications

Certifications add an extra assurance that the company you're working with is qualified to manufacture your parts. Select a company that has the relevant certifications for your industry. This will give you peace of mind knowing that a skilled and reputable company manufactures your parts.

Past Work

Are you impressed with the quality of the fabricator's past work? This is an essential question because it will give you a good indication of what to expect if you decide to work with them.

You can learn a lot about a company by looking at its past work. If you're not impressed with what you see, it's probably best to look elsewhere.

Review Their Websites

Another way to gauge a company's quality is to review its website. A well-designed and informative website is a good sign that the company is professional and takes pride in its work.

On the other hand, a poorly designed website could be a red flag that the company is not as reputable as you'd like them to be.

Ask For References

Don't forget to ask for references. A reputable company should be able to provide you with a list of satisfied customers. This is a great way to get firsthand information about the quality of the fabricator's work.

Look At Online Reviews

Aside from references, you can also look at online reviews to get an idea of what other people think about the company. Keep in mind, however, that not all reviews are created equal. Some people may be more critical than others.

It's essential to take all reviews with a grain of salt and decide based on the information you've gathered.

Visit The Company

You should also pay a visit to the company's headquarters if possible. You'll better understand the business process and how they function daily after seeing their plant.

You'll be able to see firsthand whether the company is clean and organized or if it's in disarray. It's also an excellent opportunity to meet the people working on your project.

Pricing

Finally, you'll need to consider pricing. Select a company that provides a competitive price without sacrificing quality.

Don't be scared to obtain quotations from many suppliers before deciding. This will allow you to ensure that you're receiving the greatest bargain for your money.

Bottom Line

Selecting the right sheet metal fabricator is essential to ensuring that your project is a success. Keep these tips in mind when making your decision to ensure that you select the best possible partner for your needs.

Looking for an expert in sheet metal fabrication? Try Choong Ngai Engineering. We offer a wide range of sheet metal fabrication services and have several years of experience in the industry. Contact us today to learn more.