Metal Rolling With Precision: Why It Should Matter To You

Metal Rolling is one of the most critical aspects of manufacturing. It affects everything from the quality of the product to how efficiently it can be produced. If you are a business owner, it is essential to understand why metal plate rolling with precision matters and how it can impact your bottom line.

With this in mind, let’s look into detail on what precise metal rolling is about and how it can benefit your business.

What is Metal Rolling?

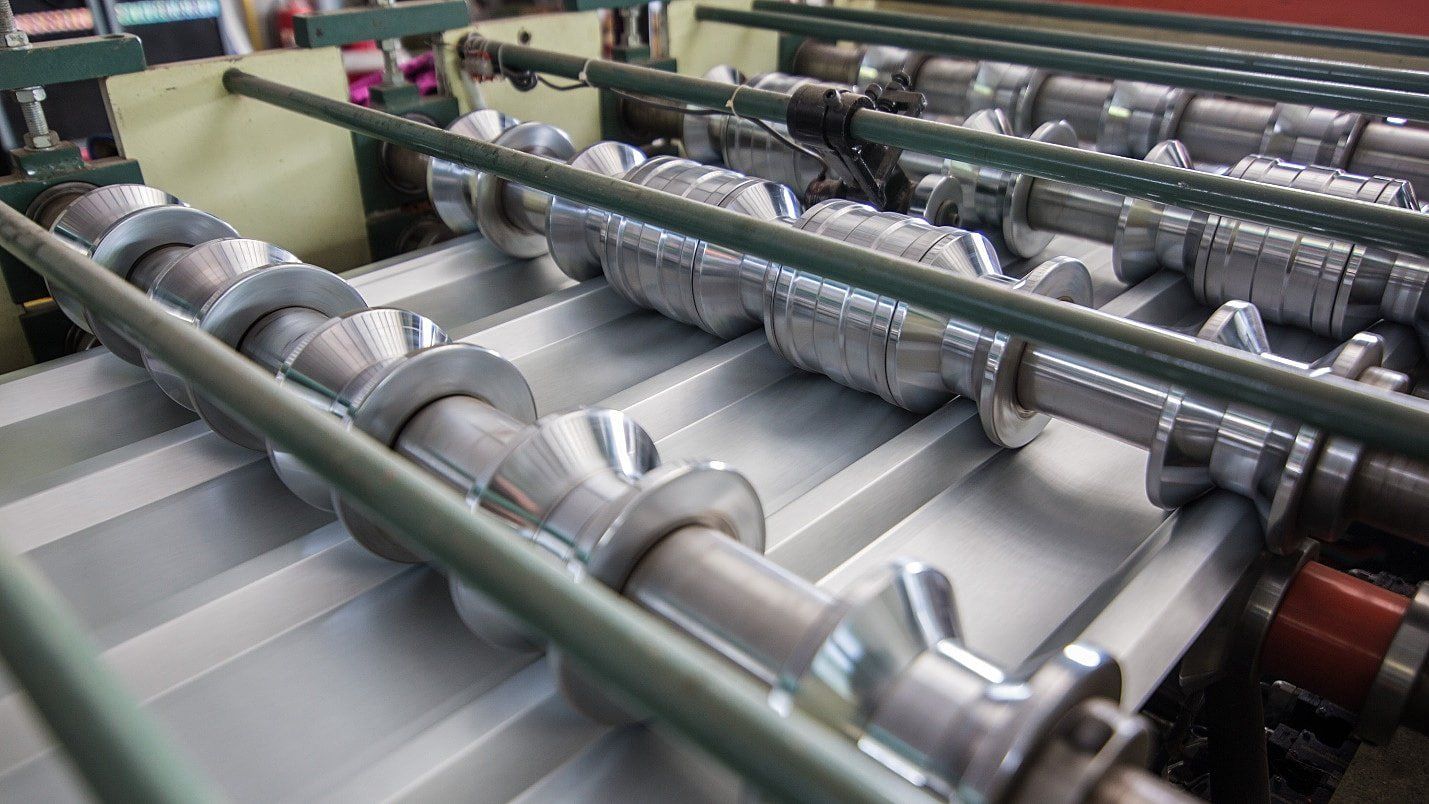

Metal Rolling is a process used to shape and form metal into the desired pieces. The method of metal rolling involves using high-quality machines that can produce consistent results. This precision is necessary because it ensures that the products you manufacture are of the highest quality.

Industries such as automotive and aerospace require precision metal rolling to create the products they need. This is why when it comes to safety, there is no room for error. These industries need to know that the parts they are making will work correctly and meet all safety standards.

How Does Precision Metal Rolling Benefit Your Business?

There are many benefits that your business can enjoy by using precision metal rolling. The most crucial advantage to note is that it can help you improve your products' quality. If you can produce high-quality products, you will be able to sell them at a higher price point. This can lead to increased profits for your business.

In addition to improving the quality of your products, precise metal rolling can also help you save money. This is because the process is much faster than other methods of forming metal. When you can produce your products quickly, you will be able to market them faster and start generating revenue sooner.

Not All Rolled Metal is Created Equally

It is important to understand that not all rolled metal is created equally. To produce high-quality products, you need to use high-quality machines to produce consistent results. This means that when you roll metal with precision, you ensure that the products you manufacture are of the highest quality and will be the same consistently. This then ensures your customers that they will receive a product that meets their expectations.

These are basic requirement to create optimum plate rolling outcomes.

Optimum plate rolling outcomes require:

Top-of-the-line machines in the industry

The machines that are used for metal rolling are vital because they determine the quality of the final product. To produce high-quality products, you need to use high-quality machines. Many different types of devices can be used for metal rolling. However, not all machines are created equal. In order to produce the highest quality products, you need to use the best devices in the industry.

Experienced roll operators

Roll operators are responsible for setting up the rollers and machines before production. They also monitor the progress of the rolling process and adjust as necessary. Experienced roll operators can set up the machines to produce consistent results. Metal rolling requires a high degree of precision, and experienced roll operators can provide this level of accuracy.

Why Other Metal Rolling Isn’t Good Enough

Metal rolling is a process that requires a high level of precision to produce the best quality products. To achieve the highest quality, it is necessary to use the best machines available on the market. Additionally, experienced roll operators are essential to ensure that the machines are set up correctly to produce consistent results.

Using inferior machines or inexperienced operators can lead to subpar products that do not meet the high-quality standards required in this industry. Therefore, it is vital to invest in the best machines and operators to produce the best quality products possible.

Looking for an expert in plate rolling services? Try Choong Ngai Engineering

We have been in the business for 19 years and have the latest technological knowledge to provide you with high-quality metal products, perfect for plate rolling services.

Our clients deserve the best quality and services, so we prioritize their needs. You won't be disappointed with our products and services.

Contact us today to learn more about our services!