Step by Step Approach to Building Your Bespoke Stainless Steel Tanks

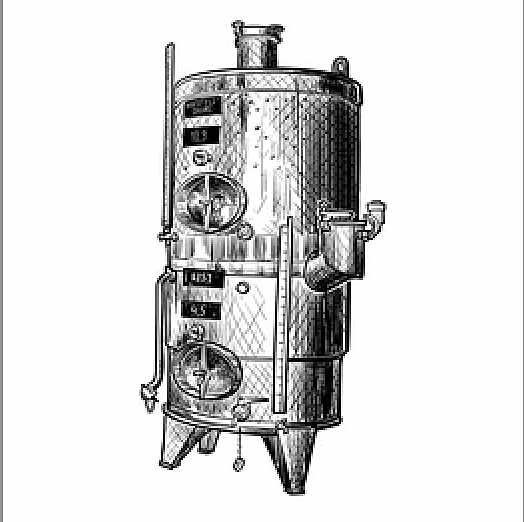

Building a stainless steel tank can seem like a daunting task. But with the right step-by-step approach, it can be easy. Not only that, but you'll end up with a high-quality tank that will last for years to come.

In this blog post, we will take you through our entire process of a custom stainless steel tank fabrication in Malaysia. We'll discuss each step of the process, from designing your tank to testing and installing it. So if you're interested in learning more about building a stainless steel tank, read on!

Our Step by Step Approach to Building Your Bespoke Stainless Steel Tanks

We make it a point to follow these steps when fabricating a custom tank for our clients:

Review Client Enquiry

The first step is to review the client's enquiry and understand their specific requirements. This step is crucial as it allows us to tailor the design of the tank to meet their needs.

Communication with Client

Our team will then get in touch with the client to discuss the specific details of their inquiry. We try to clarify any doubts they may have and ensure that we are on the same page.

Quotation

Once we go over the details of the project, we will provide the client with a quotation. The cost will depend on the size and complexity of the tank.

Winning the Project

If the client is happy with the quotation, we will proceed to step four to win the project. We will sign a contract with the client that outlines the scope of work and the terms of the agreement to do this.

Generation of Project Flow Chart

The next step is to generate a project flow chart. This document outlines the timeline and milestones for the project. It helps us keep track of the progress and ensure that everything is on schedule.

Bill of Materials

The bill of materials is a list of all the materials we will need to build the tank. This includes everything from the stainless steel sheets to the welding rods and gaskets. Some additional items that may be required are pumps, valves, and fittings.

3D Cad Design / P&ID

We want to ensure that the client is happy with the tank design before we start fabricating it. So our team will create a three-dimensional (CAD) model of the tank and send it to the client for approval.

Design Review and Approval

Design review and approval is the step where the client checks the CAD model and gives us the green light to proceed with fabrication. In this stage, the client might want to change the design. If that's the case, we will make the necessary changes and send the updated design for approval.

Manufacturing Production

After the design is approved, we will start manufacturing the tank. This involves cutting the stainless steel sheets to size, welding the pieces together, and testing for leaks.

Project Management

Throughout the entire process, our team will constantly communicate with the client. We will provide updates on the project's progress and address any concerns that they may have. This step ensures that the client is happy with the final product.

Factory Acceptance Test

Of course, we will not be able to deliver the tank to the client until it passes our factory acceptance test. This is where we put the tank through a series of tests to ensure that it meets our high standards.

Sign Off On Testing

The QA /QC team will sign off on the testing once the tank has passed. We want to make sure that the client is completely satisfied with the quality of the tank before we deliver it.

Delivery And Installation

Now on to the exciting part: delivery and installation! We will carefully transport the tank to the client's site and install it according to their specifications. Our team will ensure that the process goes smoothly and that the client is happy with the final result.

Final Thoughts

Building a custom tank is a complex process, but we are always up for the challenge. Our team has the experience and expertise to fabricate high-quality tanks that meet the specific needs of our clients. Choong Ngai Engineering is the company to call if you need a custom tank.

We specialize in metal fabrication and have a team of experienced welders who can create custom tanks to your specifications. We use the latest technology and equipment to ensure that our products are the highest quality. Contact us today to get started on your project!