Custom vs Off The Shelf Hydraulic Cylinders: Which Is Better?

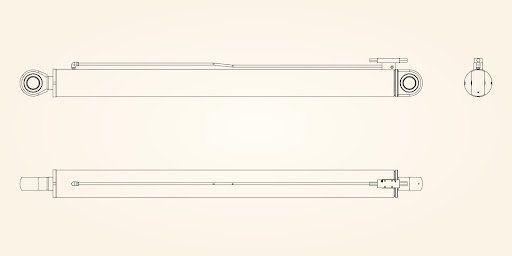

Are you currently deciding whether to purchase an off-the-shelf hydraulic cylinder or looking for a fabricator to build a custom hydraulic cylinder? Off-the-shelf hydraulic cylinders are frequently in stock and ready to ship, making them a speedy fix if your hydraulic system has failed beyond repair. While custom hydraulic cylinders, you have the freedom to create a hydraulic cylinder that precisely fits the needs of your application.

Each option has advantages, so your choice will mostly depend on the design specifications and application. Let's look at the difference between these hydraulic cylinders to help you make a better decision.

What are custom hydraulic cylinders?

Custom hydraulic cylinders are built to address the requirements of your application specifically. Instead of availability, important needs like lifting capacity and operating environment dictate the design, producing the best cylinder for your intended usage.

Other components, such as piston rods and barrels, are made to the exact length and diameter needed. In order to best fit a particular application, upgraded materials, coatings, and finishes can be used, and valves, manifolds, and electronics can be built right into the design. With a seal design tailored to its intended application, extreme environmental temperatures can be accommodated, such as subarctic conditions or close to a furnace.

Numerous mounting connection techniques are available, and port sizing and location can be tailored to match the overall equipment design. Although making each cylinder may cost more upfront, custom units frequently pay for themselves over time with better performance and fewer maintenance expenses.

When prototyping, a custom design can be developed and improved repeatedly until the best option is obtained.

What are off-the-shelf hydraulic cylinders?

In order to fit a variety of hydraulic systems, off-the-shelf cylinders are manufactured in large quantities. They are available in stock at your local retailer, offering a quick and affordable choice that can almost match your needs.

An off-the-shelf hydraulic cylinder will be beneficial when equipment is down, and a replacement is required quickly. When producing new equipment, a standard hydraulic cylinder is an ideal choice. The cylinder can be found early in the design process, and the corresponding hydraulic components are built around it.

While off-the-shelf cylinders may be appropriate in these circumstances, a compromise is frequently made in terms of the quality of the design and the materials used. For instance, the barrel might be bigger than you need it to be, and you might have a few options for rod material and diameter.

Some off-the-shelf cylinders come equipped with integrated features like valves, manifolds, and electronics, but finding them can be challenging, and they were not made with your intended use in mind.

Existing equipment's compatibility, safety, and space issues can increase maintenance costs and downtime. Port orientation can be problematic, misalignment is common, and lower-quality components can degrade quickly. This puts stress on the cylinder and its connecting sections.

When choosing an off-the-shelf cylinder for a new piece of equipment, it is frequently discovered that this is not the best option. Limited mounting options, seals that might not be suited for the intended use, and a small lifting or load capacity can all impact the performance of the equipment.

Advantages of Custom Hydraulic Cylinders

Flexibility

Constructing a hydraulic cylinder with load and lift capacity is one of the main advantages of custom hydraulic cylinder design. Custom hydraulic cylinders can be designed while keeping ISO or industry requirements in mind. These hydraulic designs can be altered in various ways, including component materials, compactness, high efficiency, and mounting alternatives.

Durability

Custom-built cylinders can be designed for specific operating situations such as high ambient pressure in deep-sea habitats, high ambient temperatures near furnaces and other heat sources, or extremely low temperatures. They may also be strong enough to function even after being in the same extended or retracted posture for decades or even after making repeated, rapid movements with varying force.

Third-party approvals

In addition to providing certificates of conformity and permitting independent testing by your third-party agents, custom cylinder producers can construct cylinders to any design specifications your third-party insurance company demands.

Disadvantages of Custom Hydraulic Cylinders

Cost

While designing and manufacturing each cylinder may initially cost more, customised units frequently pay for themselves over time by delivering higher efficiency and requiring less maintenance.

Requires experience

Another significant factor is the technical team you collaborate with while creating custom hydraulic cylinders. Experience is an element to take into account when building a custom cylinder. Still, other variables to assess before choosing a custom-built hydraulic cylinder include workflow procedure, turnaround times, and unique and industry-specific solutions.

Advantages of Off-The-Shelf Hydraulic Cylinders

Availability

Standard hydraulic cylinders and components can be obtained off-the-shelf, making them a convenient and affordable option when replacement parts are needed immediately. Off-the-shelf hydraulic cylinders can be made using high-quality materials and perform adequately as replacement OEM hydraulic cylinders and OEM component replacements. Standard choices are a hassle-free approach to getting your mobile equipment back in operation if you know the manufacturer and product number for the cylinder or component.

Cost

Due to the mass production of off-the-shelf hydraulic cylinders, the price of it is lower than a custom hydraulic cylinder. Therefore, they are ideal to be utilized for developing new equipment. These standard hydraulic cylinders can be found in the early stages of the process, where the design is developed based on these off-the-shelf hydraulic cylinders.

Different options available

The differences in cylinder design and production are determined mainly by the industry and application. Each type employs a different approach for internal details and how the end caps are fastened to the cylinder barrel. Some of the different kinds of off-the-shelf hydraulic cylinders include:

- Tie-rod cylinders

- Telescopic cylinders

- Welded rod cylinders

- Single-acting cylinders

- Double-acting cylinders

Disadvantages of Off The Shelf Hydraulic Cylinders

Maintenance

When an off-the-shelf hydraulic cylinder is used in a machine that was not intended for, maintenance can be challenging, raising the cost of machine downtime.

Approval

Most standard cylinders lack the third-party authorization required for equipment in many industries. In particular, the offshore and marine sectors demand that all machinery be built and tested to exact specifications and backed by thorough manufacturing and testing documentation to demonstrate its safety.

Choose The Ideal Hydraulic Cylinder To Get Optimum Results

When deciding whether a standard-built hydraulic cylinder or a custom-made hydraulic cylinder is best for you, your types of applications can act as a solid basis. Speak to a qualified metal fabricator in Malaysia if you think a custom hydraulic cylinder is the best choice for you but are unsure where to start.

Additionally, you must carefully take into account the insurance, safety, and maintenance requirements that will be associated with the hydraulic machine that you are designing.

Looking for a quality custom metal parts company in Malaysia ? Choose Choong Ngai Engineering!

So, if you're looking for

custom metal work in Malaysia, visit us at

Choong Ngai Engineering today to speak to our experts. We at Choong Ngai Engineering have years of experience and knowledge to answer your doubts or concerns, and we ensure to provide you with the quality solution you're looking for.

Call us now!