What Are Linear Slides And Their Application

Have you ever wondered how the world of devices and heavy equipment spare parts functions so efficiently? Say hello to the invisible heroes of motion - linear slides. In the world of engineering and mechanical design, precision and efficiency are critical. This is where linear slides enter the picture as essential heavy equipment spare parts that enable accurate and smooth motion in various applications.

The uses for linear slides are as broad as they are important, ranging from manufacturing to robotics to medical equipment. In this article, we'll delve into the field of linear slides and examine their essential traits, functionality, and various ways that they're used in different areas to boost productivity, increase accuracy, and promote innovation.

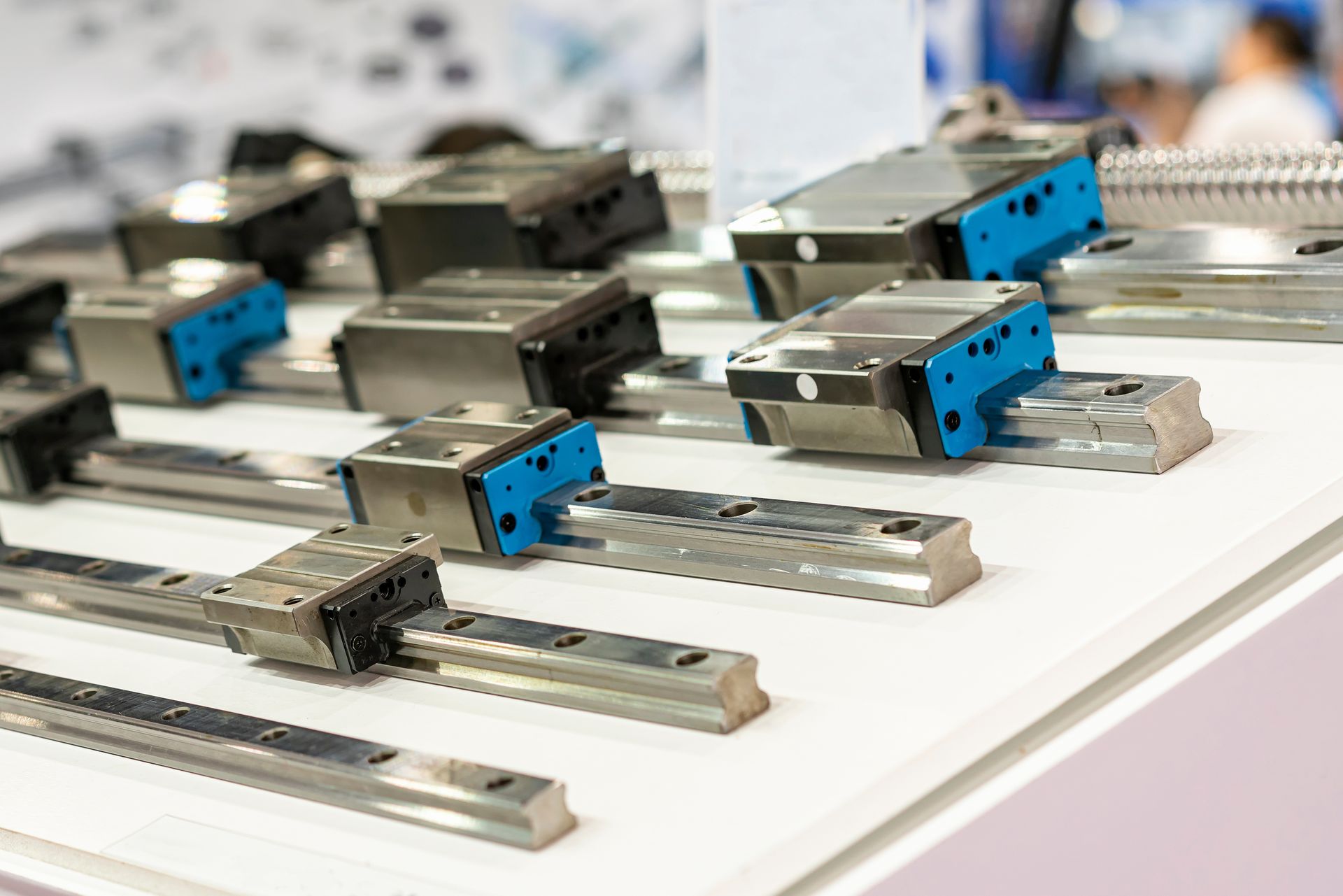

What Are Linear Slides?

Linear slides, also known as linear guides or linear-motion bearings, are forms of bearings that allow for frictionless movement along a single axis. Moving pieces in a straight line along any of the three-dimensional axes is a common need for mechanical equipment and devices such as:

- Machine tools

- Robotics

- Actuators

- Sensors

When in contact with different heavy equipment spare parts, free translational motion is constantly resisted by friction, which is the force generated by two bodies moving in opposite directions. The load administered to the surface in contact and the coefficient of friction of that surface determine how much frictional force is applied.

Low friction and high precision are the two primary features sought for movement with the following characteristics:

- Low power consumption

- Less tool wear

- Lower heat generation

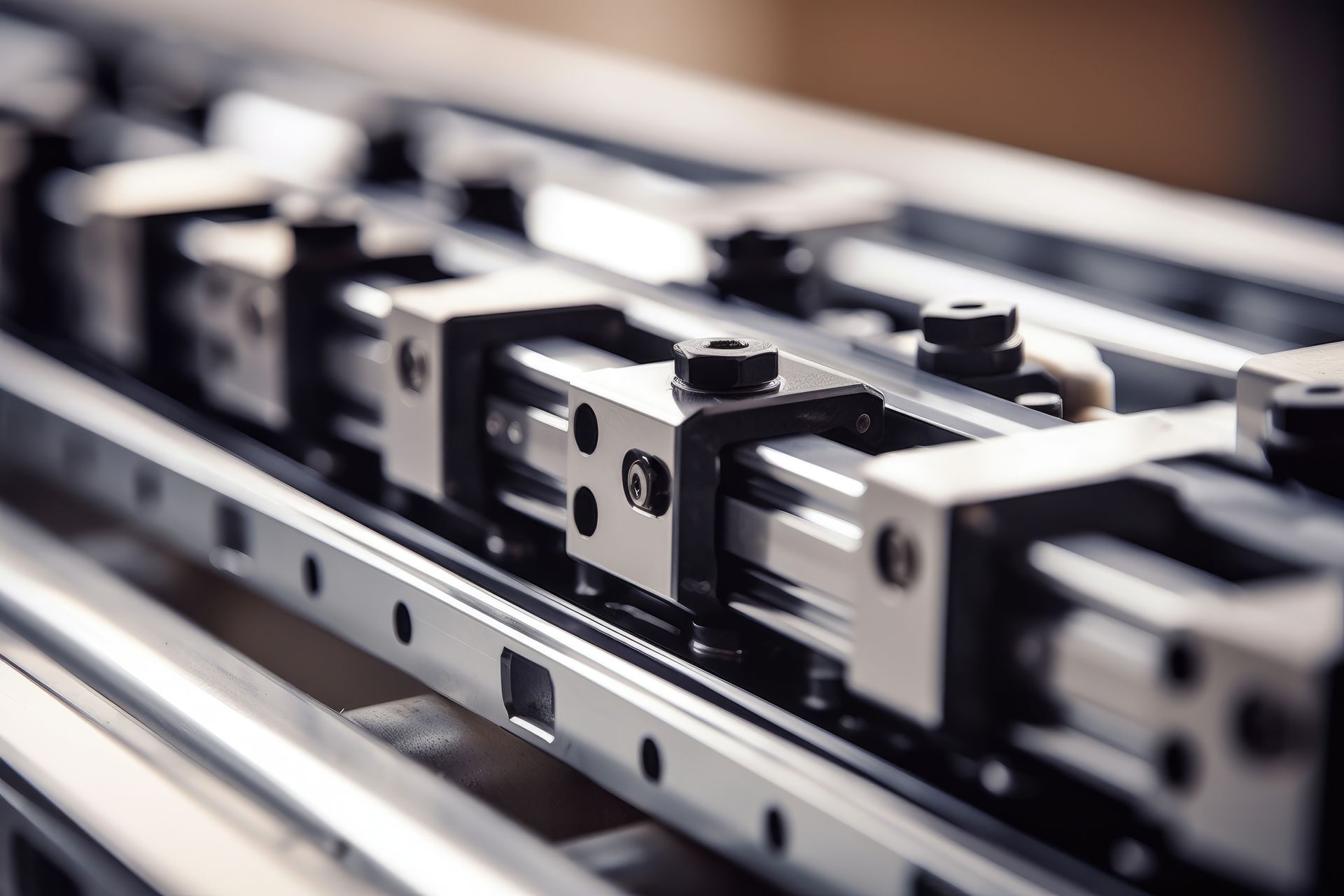

A linear slide is merely one component of a linear motion machine, which also includes:

- Power screws

- Actuated cylinders

- Linear motors

- Rack and pinion assemblies

The only time linear slides are utilised is to guide motion. Power is transferred by using additional machine components.

How Does It Work?

The main part of linear slides is the bearing, which can be any of the following:

- Rolling element

- Plain surface bearing

- Magnetic bearing

Rolling Element

A rolling element reduces the area of contact with the rubbing surfaces by using balls or rollers. Races are the surfaces on which these elements roll. Ball bearings are rolling element bearings that use rolling balls, whereas roller bearings are those that use rollers. Ball bearings concentrate the point of contact.

If the surfaces can withstand the indefinitely high contact stress created, the area of contact can be decreased to an infinitely small point. In actual practice, a limited contact region is created by a bit of deformation of the ball and racing surfaces.

Ball bearings can only support light weights because of their small contact area. The quantity of balls in contact is increased to counteract the significant contact stresses generated. To do this, new rows of balls and races are added.

Plain Surface Bearing

Plain surface bearings sustain a load and permit motion using sliding surfaces rather than rolling components. The materials and coatings used in plain surface bearings have low friction coefficients and require little lubrication.

PTFE and graphite are two composite materials that some plain surface bearings are constructed of, and they often have a metal backing. This is known as dry lubrication. It prevents metal-to-metal contact between the sliding surfaces and offers the metal backing's properties for heat dissipation. As PTFE and graphite bearings are worn down, the worn-off particles develop into a lubricating layer.

Plastic plain bearings have a similar feature. However, they lack heat dissipation and operate as thermal insulators.

Magnetic Bearing

By rejecting or attracting the moving object, magnetic bearings enable near-frictionless motion. Magnetic bearings utilise the magnetic forces generated by electromagnets to lift the object instead of using pressurised fluid.

Due to their powerful forces, magnetic bearings are suitable for high-load applications. However, due to potential interference from attached devices and relatively high energy consumption, this device only has a limited number of applications.

Types Of Linear Slides

Linear slides exist in various sizes and shapes for moving objects in a straight line. Every type offers a distinct set of capabilities according to specific requirements and uses.

Let's explore the intriguing range of linear slides to see how they enable our devices and gear to move, glide, and function flawlessly.

Dovetail Slides

These are linear slides that use lubrication and plain surface bearings with a low coefficient of friction. Their names come from protrusions that fit into identical negative geometry and have a dovetail shape. While the negative is built into the carriage, the protrusion is often on the stationary rail or base.

A dovetail table is another name for this arrangement. Slides made of dovetails are strong and can sustain lateral and radial loads. These are usually applied to powerful machinery like the following:

- Lathes

- Shapers

- Milling machines

Boxway Slides

Boxway slides are plain surface bearings, like dovetail slides. However, these feature a square gib with flanges at the top, making a T shape rather than a protrusion in the manner of a dovetail. Since there is more projected surface area in contact between the carriage and the rail than with dovetail slides, they can support greater weights.

Sleeve Bearing Slides

Instead of mating tongue and groove geometry, this type of design uses cylindrical surfaces. Journals and bushings are the names of these surfaces. The journal is a long shaft that serves as the guide rail positioned on the base, whereas the bushing resembles a hollow cylinder built within the carriage.

Sleeve-bearing slides have the benefits of being easy to assemble and having the capacity to support loads applied in any direction. However, they are not as sturdy as dovetail and boxway slides and can only be utilised for low to medium-weight scenarios.

Understanding The Role Of Linear Slides Will Help You Appreciate This Component More

Linear slides as heavy equipment spare parts have many uses, highlighting how vital they are for boosting productivity, precision, and innovation in various fields. These modest heavy equipment spare parts are the unsung heroes that make the intricate machinery of our daily lives run smoothly with a sharp eye for detail and a touch of charm.

It is obvious that linear slides will continue to be at the forefront of advancement as technology develops, influencing how we engage with and utilise the power of motion.

Looking for high-quality heavy machinery spare parts in Malaysia? Choose Choong Ngai Engineering!

If you're looking for a

heavy equipment spare parts contractor in Malaysia to help you determine the ideal wrench for your projects, visit us at

Choong Ngai Engineering today to speak to our experts. We at Choong Ngai Engineering have years of experience and knowledge to answer your doubts or concerns, and we ensure to provide you with the quality solution you're looking for.

Call us now!