What Is A Ball Screw And How Are They Used?

Have you ever questioned how industrial robots operate with such accuracy or how easily your car's automated windows open and close? The answer can be found in the ball screw, a seemingly insignificant yet crucial heavy machinery spare part in Malaysia.

With the help of these sophisticated heavy equipment spare parts in Malaysia, contemporary machinery can move smoothly and precisely. So, if you're into mechanics or want to know how things move so smoothly, let's delve into the mysteries of ball screws and discover how they discreetly power the systems that improve our lives.

What Is A Ball Screw?

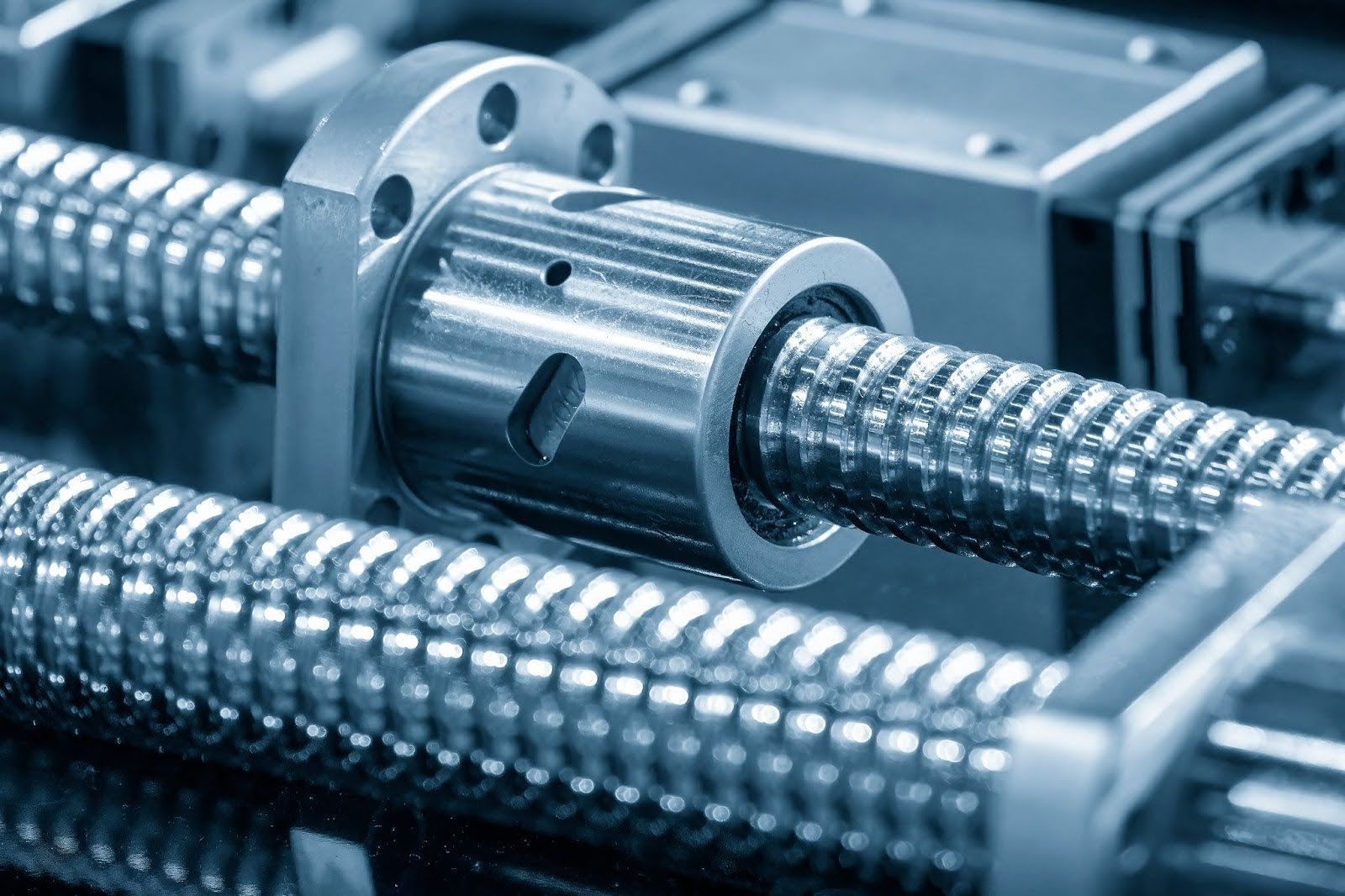

Ball screws are linear mechanical devices made up of a screw shaft and a nut with a ball inside that rolls between the spiral grooves on both parts. The basic function of ball screws is to transfer rotational motion to linear motion. Ball nuts are used to send forces to a load that is either fixed or moving with great accuracy, precision, and repeatability.

Rolling balls in a spiral groove are what set ball screws apart from other types of screws; they replace sliding friction with rolling friction and lessen mechanical contact within the screw assembly.

This technique considerably reduces the friction produced, which yields an excellent power conversion. The ability of screws to convert the energy used to create rotational force into the linear distance travelled serves as a measure of their efficiency.

The Various Types Of Ball Screw

Ball screws, like the other tools in a toolbox, exist in an extensive range of types, each tailored for a particular task.

Below, we'll explore the wide variety of ball screws available. We'll look into how these variants are adapted to fulfil specific requirements while still adhering to the same fundamental standards of precision and dependability.

Deflector-Type Ball Screws

To direct the balls back to the neighbouring groove, which serves as their starting point, deflectors are utilised in this type of ball screw to lift the balls over the diameter of the screw shaft. Every turn requires one deflector to close the ball's path. As a result, the number of turns is always the same as the number of circuits for internal ball return systems.

This design is put to use in situations that necessitate incredibly thin conductors. The small form factor makes it an excellent choice for tight clearance applications.

The ball can be returned through a series of tubes or caps, each of which can be configured to form a separate but neighbouring circuit.

End Cap-Type Ball Screws

End caps are attached to this type of ball screw to help the balls move through a tube inside the nut, leading them back to where they started. This design works well with high-lead ball screws because it can handle the force of the balls moving quickly.

Return Pipe-Type Ball Screws

With a return pipe-type ball screw, the ball bearings in the ball screw unit can be sent back to where they were first deployed. The design has a pipe or closed loop that moves the ball bearings from the screw's end to the nut's end and back again.

This system comes in handy when keeping the ball bearings inside the mechanism and stopping them from rolling out, particularly if the ball screw is standing up straight.

Benefits Of A Ball Screw

Ball screws are mechanical marvels with a wide range of benefits, which become increasingly apparent as we learn more about them. When it comes to precision and efficiency, ball screws are the unsung heroes behind various industries.

Here are some of the benefits that these heavy equipment spare parts can provide to any heavy machinery.

High Efficiency

Ball screws have a reputation for having a high mechanical efficiency that frequently exceeds 90%. This means they waste less energy and require less power since a larger proportion of the input torque is converted into useful axial force.

Enhanced Accuracy

When it comes to linear motion, the preciseness and accuracy offered by ball screws is unparalleled. As a result of their low backlash, there is little play or lost motion, which makes them perfect for situations where exact positioning is needed.

Broad Range Of Applications

Ball screws are widely used in industries where precise and reliable linear motion is required, such as:

Aerospace- Automotive

- Robotics

- Medical equipment

- Industrial automation

Understanding The Basics Of These Heavy Machinery Spare Parts Is Vital For A Successful Project

To sum up, ball screws are vital heavy machinery and equipment spare parts used in Malaysia and worldwide. They are essential to adequately operating heavy equipment because they provide accurate linear motion, effectiveness, and dependability.

It doesn't matter if you're in manufacturing, construction, or any other industry; ball screws are essential in pushing innovation and enhancing the performance of heavy equipment spare parts in Malaysia and beyond.

Looking for high-quality heavy machinery spare parts in Malaysia? Choose Choong Ngai Engineering!

If you're looking for a heavy equipment spare parts contractor in Malaysia to help you determine the ideal wrench for your projects, visit us at Choong Ngai Engineering today to speak to our experts. We at Choong Ngai Engineering have years of experience and knowledge to answer your doubts or concerns, and we ensure to provide you with the quality solution you're looking for. Call us now!