5 Benefits Of Installing Stainless Steel Fabrication In Homes

Despite its simple looks, the effects of stainless steel fabrication on houses are significant. Due to its distinct qualities that makes it available in various shapes and patterns to meet your needs, stainless steel is frequently used in fabrication. Additionally, it's an excellent fix for a lot of household appliances.

Let's look at some of the ways that stainless steel fabrication is incorporated into homes.

Types of stainless steel fabrication for homes

One of the most often used materials, particularly in the home, is stainless steel. Most household objects, including our house structures, wouldn't be as durable without stainless steel.

Railings

Stainless steel railings serve an important part in assuring people's security and protection in a range of applications, including:

- Balconies

- Staircases

- Decks

- Porches

- Platforms

Additionally, stainless steel railing design is an essential component of architectural or home renovation projects for adding decorative and innovative elements. Besides that, stainless steel is the suitable choice for railings because of its remarkable durability and resistance to dust and corrosion. It also involves easy installation and low maintenance.

Cutlery and utensils

Most of the cutlery and utensils we use daily are made of stainless steel. The combination of chromium and nickel used to make stainless steel makes it a remarkably robust and durable material that won't rust or stain.

Appliances

Stainless steel is the predominant material used in most modern household appliances, including:

- Refrigerators

- Televisions

- Sinks

- Ovens

A stainless steel appliance will withstand stains and rust despite frequent messy usage and won't be easily scratched during accidental collisions. Maintenance is effortless with a stainless steel surface because a spill can be quickly cleaned up, and dull surfaces can be polished with a clean rag.

Additionally, stainless steel is non-porous, making it more resistant to lingering bacteria and germs. As a result, stainless steel appliances are ideal for families with children and pets.

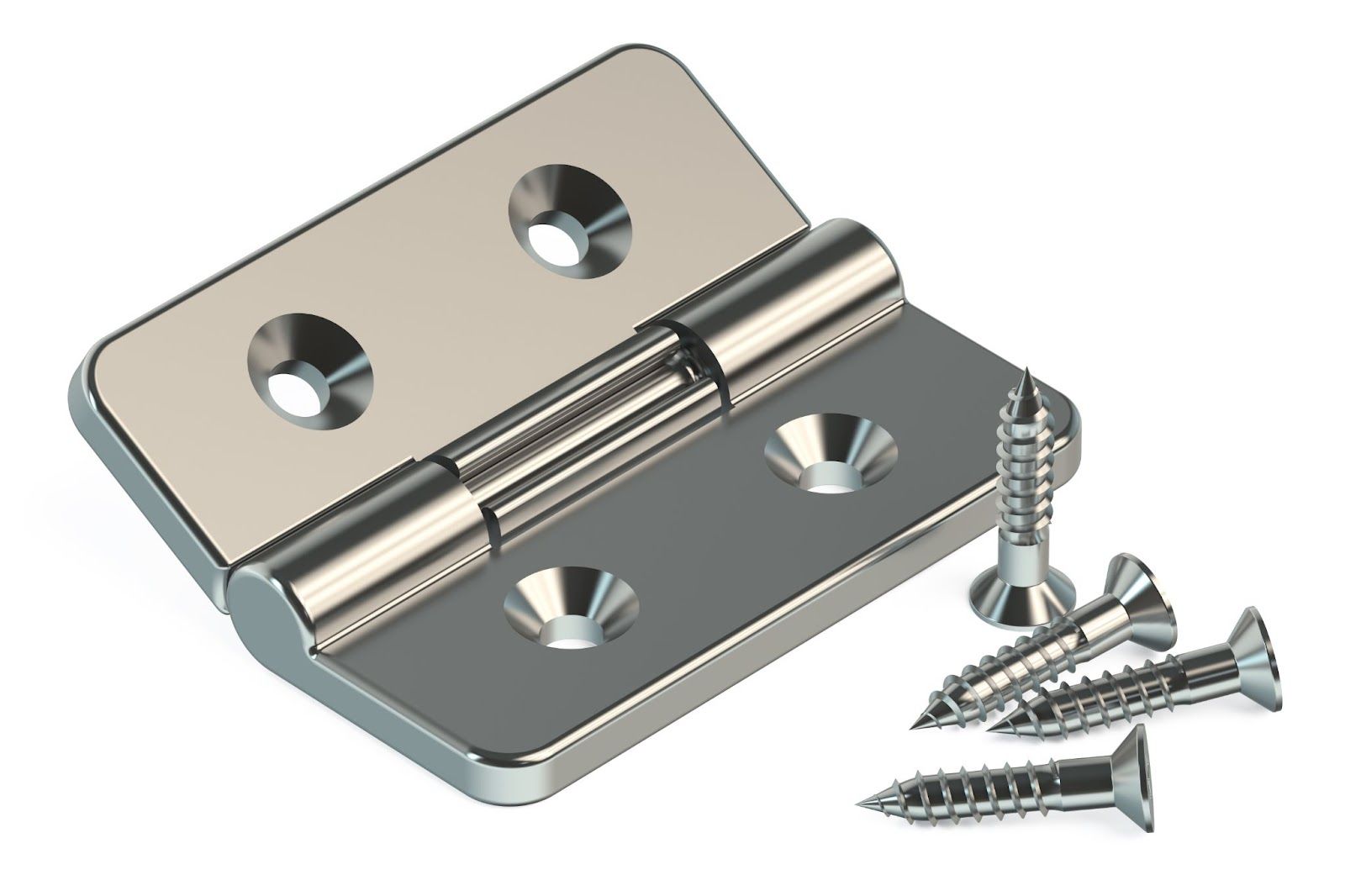

Screws and Hinges

Stainless steel is used to make a lot of the screws and hinges in your home. Due to its greater resistance to rust and corrosion, as well as its capacity to endure extremely high temperatures, stainless steel is an excellent option.

Structure

Roughly 70% of the frames for multi-story buildings are made of structural stainless steel work. Stainless steel is preferred in this setting because of the following factors:

- It adheres well to concrete

- Durable

- Consistently cost-effective

Depending on the size of the project, the building time can be reduced by 20–40% when using a structural steelwork frame rather than taking several weeks.

Water Features

Due to its versatility for modern and traditional landscapes, stainless steel has become the most preferred material for water feature ideas. It can be easily sculpted into shapes with strong, geometric lines to smooth, flowing curves. It is also incredibly beautiful and may be polished to a high gloss finish or brushed to provide contrast and artistic charm.

Even the darkest corners of your garden space will be illuminated by a stainless steel water feature, which will also mirror the sky and catch the sun's rays.

Storage

Stainless steel is also utilised in home storage in steel cabinets and shelving units. Aside from remaining sturdy, stainless steel is also capable of the following:

- Withstanding huge loads

- Resistant to extreme heat

- Secure

Benefits of stainless steel fabrication for homes

Unlike other materials like aluminium and wood, stainless steel is flexible and highly durable. Stainless steel's durability is generally preferred since it helps to maintain ideal hygienic conditions. The benefits of stainless steel fabrication exceed its drawbacks.

Durable

The durability of stainless steel is widely recognised. It's great to own something that will last forever because it means you won't have to replace it for a while.

When you choose stainless steel fabrication for your house, you can save cost on repairs. It's one of the most appealing benefits of choosing stainless steel fabrication as a solution.

Cost-effective

When compared to other materials, stainless steel products are among the most affordable. Since steel is more durable and flexible, it might take a long time to erode, saving you money on repair costs.

Additionally, most pricing is reasonable and consistent for the consumer. When purchasing home appliances, most people try to save money and won't think twice about buying an affordable device.

In other words, stainless steel fabrication requires minimal care. Thus having it in your home frees up your time to concentrate on other things or activities rather than routine maintenance.

Sustainable

Sustainability is one of the most important factors to consider when choosing the ideal fabrication for a house. Consequently, stainless steel has the distinct benefit of providing sustainability. Not only are these materials economically viable, but they are also environmentally sustainable.

Products made of stainless steel are entirely recyclable. The adaptability of these products is remarkable. A sizable amount of your stainless steel door or wall replacement would still be recyclable.

Safe

When selecting home materials, safety is always a top priority. Due to the inert and non-reactive materials used in stainless steel fabrication, it is regarded as safe. Additionally, stainless steel is mould-resistant and easy to clean.

The thought of using a sink that is tough to maintain can be daunting. As such, stainless steel fabrication is preferred by the majority of healthcare facilities and the food service sector. Keeping other materials pristine is challenging, even with necessary cleaning equipment.

Furthermore, stainless steel is resistant to fire and termites. Steel does not burn and melts only at extremely high temperatures.

Aesthetically pleasing

Aesthetics is another significant reason many homeowners prefer stainless steel fabrication in Malaysia. It has a sophisticated and captivating appeal. Additionally, it's one of the materials that complement and blend with other appliances in your home, creating the pleasing design that every homeowner desires.

Looking for a quality stainless steel fabrication company in Malaysia ? Choose Choong Ngai Engineering!

So, if you're looking for a stainless steel fabricator in Malaysia, visit us at Choong Ngai Engineering today to speak to our experts. We at Choong Ngai Engineering have years of experience and knowledge to answer your doubts or concerns, and we ensure to provide you with the quality solution you're looking for. Call us now!