The Various Types Of Wrenches And Their Uses

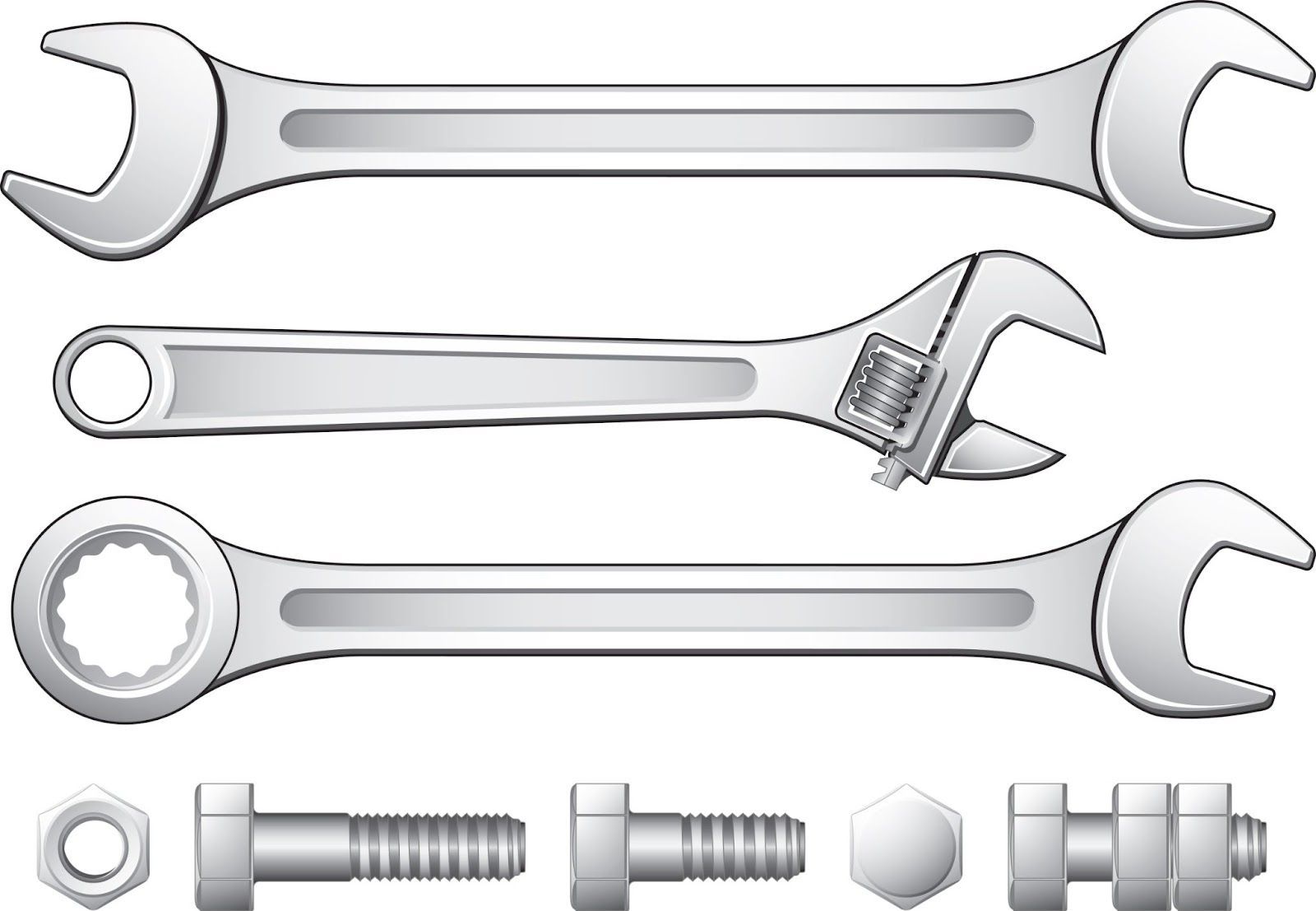

Whether it is mechanical labour or a simple tightening of a bolt at home, wrenches are a must in any toolbox because they offer an effective way to tighten and loosen bolts. Wrenches exist in various forms, each created to fulfil a specific function, from straightforward domestic repairs to complex car maintenance.

Let's look at the wide variety of wrenches on the market, highlighting their distinctive designs and the applications that they are most useful for. Understanding the various wrench types and their particular functions equips experts and DIY enthusiasts to take on a variety of jobs with confidence.

So, whether it is an adjustable wrench's flexible adaptability or a torque wrench's specialised features, you can pick up the proper wrench without a second thought for your next project.

What Is A Wrench?

A wrench is a standard removal and installation tool. Thus, using the principle of leverage, this hand tool is used to rotate any threaded fasteners in apertures or through holes, including:

- Bolts

- Screws

- Nuts

The wrench usually features apertures or sleeve holes for gripping the bolt or nut on one or both ends of the shank. In order to rotate a bolt or nut, an external force must be supplied to the shank in the direction of the thread rotation. The wrench is often made of drop-forged chrome vanadium alloy tool steel.

The Various Types Of Wrenches

Here are the various types of wrenches and their functionality to help you better understand the purpose of a wrench.

Box Wrench

This is the most elementary fixed-size collar wrench available. To hold the sides of the bolt or nut, this sort of wrench features a closed-end opening. The torx wrench's working surface is fixed, and in order to live up to various standards, the torx ring's specifications will be engraved on the wrench.

Most closed apertures are dodecagonal or hexagonal; a hexagonal bolt or nut can be rotated in either shape. Among these, the dodecagon-shaped opening is beneficial in places with little room since it could encompass the bolt or nut at twelve angles. Additionally, a dodecagon-shaped opening is typically used for the initial loosening and final tightening of a screw cap.

Open Wrench

This particular style of wrench features an opening in the shape of a U at the end, allowing a secure grasp on either side of a bolt or nut. These wrenches often have two ends, each with a different size opening. Given that the opening of this kind of wrench has no flexibility, bolts and nuts of varying sizes must be matched one by one to the wrench. Typically, the wrench is labelled with the opening specification.

The distance between the opposite edges of the hexagonal or quadrangular nut indicates a wrench opening. The entire set of wrenches will range in size from small to large, with each size being made to the same specs. Additionally, a collection of wrenches frequently includes five to twenty wrenches, depending on the range of sizes.

Hexagonal Wrench

Standard thick steel wire in the shape of an L has a common hexagonal cut surface and comes in various sizes. An L-shaped steel hexagonal rod and a T-shaped steel hexagonal straight rod are both fastened horizontally to the plastic handle.

This kind of wrench works well for driving bolts and screws with hexagonal grooves in the head as well as twisting bolts and screws with hexagonal grooves.

Torque Wrench

This wrench is capable of tightening a nut to a specific torque. When tightening a nut, a torque wrench is a tool that has a specific mechanical design, typically in the shape of a socket wrench. Using a torque wrench enables the user to apply a specified torque value when screw and bolt tightness is crucial.

Set of Socket Wrenches

This kind of wrench features a hollow socket at the end that slips over the end of a bolt or nut. Sockets are sometimes connected with handles, and universal joints and sockets are utilised alongside other tools. The clip seat offers the benefit of an integrated one-way mechanism, such as a ratchet, that allows users to swing back and forth without releasing their grip.

Dual-purpose Wrench

This kind of wrench has two ends, one of which is open, and the other is closed. The two ends are the same size, and the same-specified bolts or nuts are inserted into both ends. A dual-purpose wrench is an essential instrument for the following tasks:

- Repair

- Maintenance

- Installation

Pipe Spanner

In order to maximise the gripping force and clamp the smooth pipe wall, a pipe spanner, sometimes referred to as a pipe wrench, features strong serrated teeth on both sides of its moveable jaw. The opening's size may be altered by adjusting the nut, and it is perpendicular to the handle's body length to accommodate revolving steel pipes or other circular work materials.

It is a standard instrument for pipeline installation and repair. Additionally, a pipe spanner is also used to fasten or disassemble the following:

- Pipes

- Pipeline Accessories

- Spherical pieces

Understanding The Tool That Plays A Vital Role Across Various Sectors To Maximise Its Functionality

There are many options available in the broad and specialised field of wrenches to suit different activities and sectors. By enabling us to carry out tasks with accuracy, effectiveness, and confidence, it becomes evident that these instruments are essential allies for any mechanical job.

Looking for high-quality heavy equipment spare parts in Malaysia? Choose Choong Ngai Engineering!

If you're looking for a heavy equipment spare parts contractor in Malaysia to help you determine the ideal wrench for your projects, visit us at Choong Ngai Engineering today to speak to our experts. We at Choong Ngai Engineering have years of experience and knowledge to answer your doubts or concerns, and we ensure to provide you with the quality solution you're looking for. Call us now!